- 14

- Nov

The principle of intermediate frequency quenching of crankshaft main journal and connecting rod journal

The principle of intermediate frequency quenching of crankshaft main journal and connecting rod journal

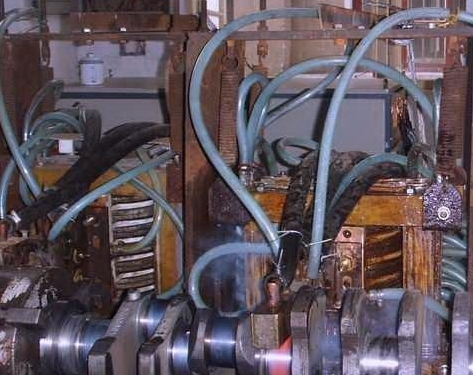

(1) Intermediate frequency induction hardening of crankshaft

The intermediate frequency induction hardening of the crankshaft will adopt a microcomputer-controlled closed-loop intermediate frequency induction heating device, which has the characteristics of high efficiency, stable quality, and controllable operation.

(2) Soft nitriding of crankshaft

For mass-produced crankshafts, in order to improve product quality, a microcomputer-controlled nitrogen-based atmosphere gas nitrocarburizing production line will be used in the future. Nitrogen-based atmosphere gas nitrocarburizing production line is composed of front cleaning machine (cleaning and drying), preheating furnace, nitrocarburizing furnace, cooling oil tank, post cleaning machine (cleaning and drying), control system and gas production and distribution systems.

(3) Crankshaft surface strengthening technology

Nodular cast iron crankshaft fillet rolling strengthening will be widely used in crankshaft machining. In addition, compound strengthening processes such as fillet rolling strengthening and journal surface quenching will also be widely used in crankshaft machining. Forged steel crankshaft strengthening methods will be more. The ground adopts the shaft journal and fillet quenching treatment.

https://songdaokeji.cn/category/products/induction-melting-furnace

https://songdaokeji.cn/category/blog/induction-melting-furnace-related-information

Nambala: 8618037961302