- 09

- Oct

1700 ℃ muffle furnace – volume 36L

1700 ℃ muffle furnace – volume 36L

【Product Model】STM-36-17

[Furnace size] 300 x 400 x 300mm

【Rated temperature】1700 ℃

【Power supply voltage】AC380V/50Hz

【Temperature control accuracy】± 1 ℃

[Applications] 1700 ℃ muffle furnace ( box-type resistance furnace ) mainly provides high-temperature heat treatment environment for industrial laboratories such as universities, scientific research institutes, factories and enterprises, and is used in metal materials, ceramic materials, nano materials, semiconductor materials, etc. The field of new materials.

1. Product description

STM series products are mainly developed for daily applications in the laboratory. High-quality furnace materials and stable temperature control systems can ensure the reliability of experimental data; the products use high-purity alumina materials as furnace materials, and high-quality silicon molybdenum rods are used for heating The component is used as a heating element, and the temperature controller adopts a microcomputer PID control module, which can achieve precise temperature control and constant temperature requirements.

2. Product features

1. The furnace material is made of imported light-weight and high-purity alumina ceramic material, which has high hardness, no powder falling at high temperature, no volatilization at high temperature sintering, environmental protection and safety, and conforms to international industry standards

2. The heating element adopts high-quality silicon molybdenum rods, which can bear large load, is stable and has a long service life; the silicon molybdenum rods are evenly arranged on both sides of the furnace, and the temperature field is uniform.

3. Patented temperature control design, fast heating speed, good temperature uniformity, can rise to 1600 ℃ in 60 minutes , which is more than 3 times higher than the same specification electric furnace sintering efficiency in the industry , safe and efficient

4. The temperature control accuracy is high, the temperature is small, with temperature compensation and temperature correction functions, the temperature control accuracy is ± 1 ℃

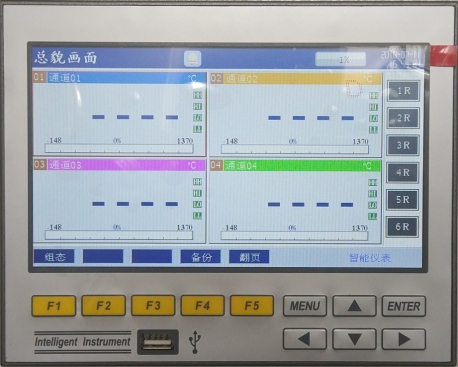

5. Adopt intelligent PID temperature control instrument, with program function, can set heating curve, can edit 30 program segments

6. One-piece structure, double-layer shell, air circulation heat insulation, excellent appearance design, beautiful and generous

7. Electronic components are all made of Delixi products, with leakage protection function, safe and reliable

8. This machine will send out an alarm signal for over-temperature in the working process, and automatically complete the protection action

9. When the instrument program setting is completed, just press the run button, and the next work will be completed automatically

10 , optional large screen paperless recorder or RS232 communication interface, real-time recording of the temperature curve, and with the memory card may analyze the experimental data and print

| product name | Muffle furnace | |

| Product number | STM-36-17 | |

| main indicators | Furnace size: 300mm (width) × 400mm (depth) × 300mm (height)

Rated maximum temperature: 1700℃ Long-term working temperature: 1600℃ Temperature stability: ±1℃ Heating rate: 1-15℃/min, can be adjusted freely according to the process Power supply power: AC380V, 13KW, 50HZ |

|

| Temperature Control System | Using Xiamen Yudian intelligent microcomputer PID temperature control instrument, SCR/SSR control, PID parameter self-tuning function, over-temperature alarm function; programmable 30 time periods, automatic heating, automatic heat preservation, automatic stop, which can meet the continuous constant temperature and temperature control requirements , Electronic components are made of Delixi products to ensure long-term stability and reliability; control accuracy: ±1℃ | |

| Heating element | U-shaped silicon molybdenum rods are installed vertically, evenly distributed on both sides of the furnace, and the temperature field is even | |

| Temperature measuring element | Type B national standard platinum and rhodium thermocouple | |

| Furnace material | The use of polycrystalline alumina ceramic fiber material, one-time molding and patented new splicing structure technology ensure the robustness and durability of the furnace. The polycrystalline alumina ceramic fiber material is one of the latest ultra-lightweight high-temperature insulation materials at home and abroad. Crystal fiber as the basic material, wet vacuum suction molding to prepare polycrystalline inorganic ceramic fiber material, good thermal shock performance and thermal stability, low heat capacity, low thermal conductivity, more than 50% energy saving compared with traditional silicon carbide furnace | |

| Furnace structure | 1. The furnace is composed of furnace materials, insulation materials and heating elements

2. The temperature control system consists of temperature control instruments, control elements and thermocouples 3. Furnace body and temperature control integrated structure, the furnace is fixed on the thermostat, the side of the furnace door opens axially |

|

| shell | High-quality cold-rolled steel plate CNC machine tools are used for cutting and processing, after welding, grinding, polishing, phosphating, pickling, and surface spraying with plastic powder, then high temperature baking, reasonable color matching, and novel appearance | |

| safety protection | Modular control, sound and light alarm signals will be issued for over-temperature and broken couple during work, and the protection action will be automatically completed; the equipment is equipped with an air circuit breaker, which will automatically bounce when a short-circuit leakage occurs, which can protect the equipment And operator safety | |

| Quality Certification | EU certification, EU TUV electrical safety certification | |

| warranty period | Non-artificial damage 12 months from the acceptance date | |

| physical dimension | 700mm×840mm×1250mm (width×depth×height) | |

| weight | 300Kg | |

| Standard configuration | 1. A furnace body 2. A temperature controller 3. A power cord of 3 meters 4. A thermocouple 5. A manual 6. A crucible clamp 7. A pair of high temperature gloves 8. A fire door 9. A spare Two silicon molybdenum rods | |

| Packing and shipping | 1. The two-layer packaging method is adopted, the inner layer of plastic film is wound, moisture-proof and rain-proof, the outer layer is thickened with a wooden bottom bracket and the plywood box body, the keel is limited, nailed, strong and reliable

2. Adopt Debon Logistics or a large logistics company of the same scale, and transport by car, door-to-door, and delivery under the car; any damage to the product during transportation shall be borne by us |

|

| Optional accessories | 1. Optional and install a paperless recorder, which can record the temperature rise data online. The recorder has a storage function and has a USB interface. The data can be copied to the computer through the U disk, and the data report can be viewed and printed at any time.

2. Optional computer communication control system, which can control the equipment in real time through the computer 3. An exhaust chimney is optional, and an exhaust port can be installed behind the furnace for the volatilization of high-temperature organic matter. 4. Optional corundum crucible, silicon carbide/corundum bottom plate, sagger and other stoves |

|

Paperless recorder |

Computer control software |

|

Alumina crucible |

Exhaust chimney |

|