- 29

- Jan

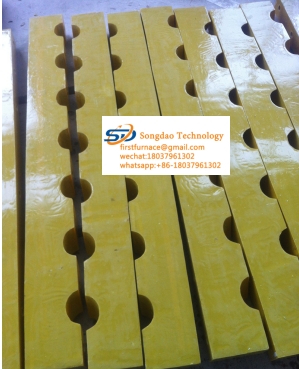

Epoxy fiberglass fixture

Epoxy fiberglass fixture

1. Product introduction of epoxy glass fiber fixture

Epoxy glass fiber clamps are also called epoxy glass fiber resin insulation clamps, epoxy glass fiber resin clamps, 3240 insulation clamps, epoxy glass fiber resin insulation clamps, 3240 epoxy glass fiber insulation clamps, etc. Epoxy fiberglass resin fixture is made of epoxy fiberglass resin and glass cloth, model 3240, with high mechanical performance at medium temperature and stable electrical performance at high temperature. It is suitable for high-insulation structural parts for machinery, electrical appliances and electronics, with high mechanical and dielectric properties, good heat resistance and moisture resistance. Heat resistance grade F (155 degrees). Processing and molding according to the customer’s drawings, the specific size of the epoxy glass fiber resin fixture, according to the customer’s drawings shall prevail.

2. Product introduction of epoxy glass fiber fixture

Epoxy glass fiber clamps are devices used to fix the processed objects in the mechanical manufacturing process so that they occupy the correct position for construction or inspection. Also known as clamps. Broadly speaking, in any process in the process, the device used to quickly, conveniently and safely install the workpiece can be called a fixture. For example, welding fixtures, inspection fixtures, assembly fixtures, machine tool fixtures, etc. Among them, machine tool fixtures are common, often referred to as fixtures for short. When processing a workpiece on a machine tool, in order to make the surface of the workpiece meet the technical requirements of the size, geometry, and mutual position accuracy with other surfaces specified in the drawing, the workpiece must be installed (positioned) and clamped (clamped) before processing . The fixture usually consists of a positioning element (to determine the correct position of the workpiece in the fixture), a clamping device, a tool setting guide element (to determine the relative position of the tool and the workpiece or to guide the direction of the tool), an indexing device (to enable the workpiece to be installed in one installation) To complete the processing of several stations, there are two types of rotary indexing device and linear moving indexing device), connecting elements and clamp concrete (fixture base).