- 24

- Nov

Principle of Induction Melting Furnace

Principle of Induction Melting Furnace

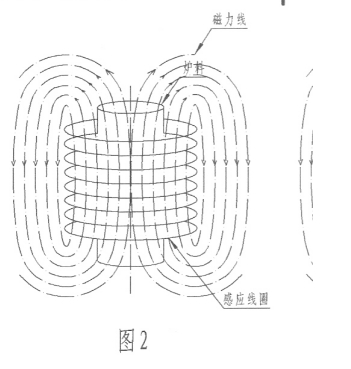

1. The core component of the induction melting furnace is a round induction coil-commonly known as an induction coil. It is wound by a rectangular copper tube into a spiral shape.

2. Pass an intermediate frequency current to the inductor, then an intermediate frequency alternating magnetic field will be generated in the middle and around the induction coil.

3. The alternating magnetic field in the induction coil cuts the metal placed in the induction coil and generates eddy currents on the surface of the metal.

4. The eddy current generated on the metal surface is very large, generally reaching tens of thousands to hundreds of thousands of amperes. Such a large current is enough to melt the metal instantly.

5. Since the alternating magnetic field directly generates eddy currents in the metal to generate heat, the efficiency of induction heating is the highest compared to flame heating, thermal radiation, arc heating and other heating methods.

6. Due to the stirring of the electromagnetic field, the composition of the molten metal liquid is relatively uniform.