- 04

- Nov

What is the difference between high alumina brick and clay brick

Waa maxay farqiga u dhexeeya leben alumina sare ah and clay brick

Lightweight high-alumina bricks usually use high-alumina bauxite clinker plus a small amount of clay. After being ground, they are poured and shaped in the form of mud by gas generation method or foam method, and fired at 1300-1500°C. Sometimes industrial alumina can be used to replace part of bauxite clinker. It is used for the lining and heat insulation layer of masonry kilns, as well as the parts that are not corroded and scoured by strong high-temperature molten materials. When in direct contact with the flame, the surface contact temperature shall not be higher than 1350℃.

Lightweight clay bricks, thermal insulation refractories refer to refractories with high porosity, low bulk density and low thermal conductivity. Thermal insulation refractories are also called lightweight refractories, which include thermal insulation refractory products, refractory fibers and refractories Fiber products. Thermal insulation refractories are characterized by high porosity, generally 40%-85%; low bulk density less than 1.5g/cm3; low thermal conductivity, generally less than 1.0W (m.K). It acts as a heat insulation material for industrial kilns, which can reduce the heat loss of the kiln, save energy, and reduce the quality of thermal equipment. Thermal insulation refractories have poor mechanical strength, abrasion resistance and slag corrosion resistance, and are not suitable for the load-bearing structure of the kiln and direct contact with slag, charge, molten metal and other parts.

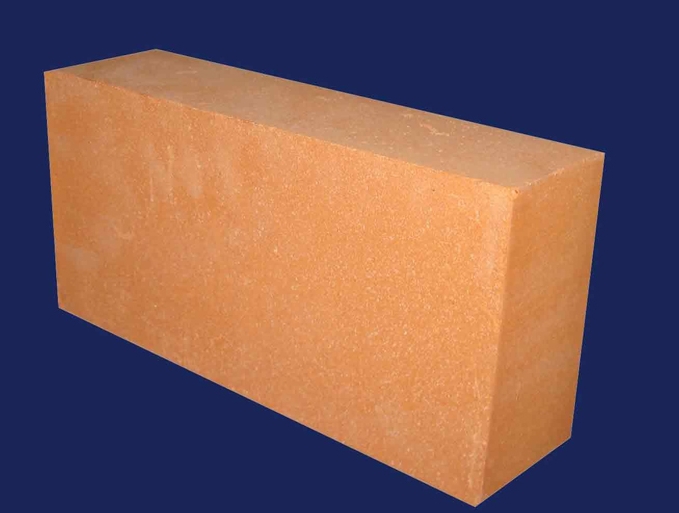

There are differences in aluminum content, unit weight, use temperature, and color. For example: 75 high alumina bricks and 43 clay bricks, 75 units weighing more than 4.5kg. 43 of about 3.65kg, the use temperature of 75 high alumina is about 1520, 43 of bricks are about 1430, the color is 75 in white, and 43 is loess. In short, the difference is huge.