- 11

- Feb

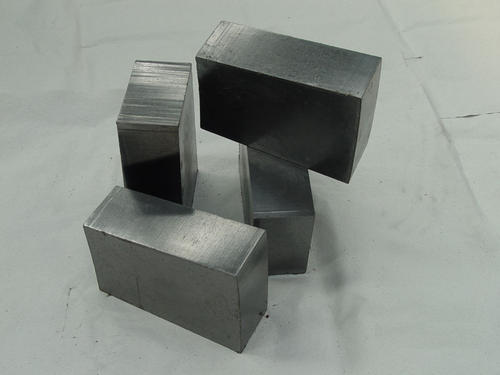

What are the types of refractory bricks?

Које су врсте ватросталне цигле?

Refractory bricks are of different types and use occasions. Refractory bricks are a kind of refractory material with a relatively high cost performance. Users can choose the appropriate refractory bricks according to the size and specifications of the product and the different materials. What are the performances of the various types, let me introduce you to them below.

Our company has refractory bricks, light mullite refractory bricks, refractory bricks for carbon roasting, silicon-moon refractory bricks, light refractory bricks, and magnesia carbon refractory bricks.

Mullite lightweight refractory bricks are high-alumina refractory materials with mullite as the main crystal phase. Generally, the alumina content is between 65% and 75%. In addition to mullite, the mineral composition with lower alumina also contains a small amount of glass phase and cristobalite; the higher alumina content also contains a small amount of corundum

The production of carbon products mainly uses primary and secondary roasting furnaces and graphitization furnaces, collectively referred to as carbon products roasting furnaces. Carbon products roasting furnaces can be divided into batch furnaces, continuous furnaces, chamber furnaces, ring furnaces, tunnel furnaces, rotary kilns or resistance furnaces according to the structure and operation methods.

Silica-mold bricks were successfully trial-produced in the early 1990s. They were once called HMS high wear-resisting bricks, and their wear resistance coefficient is more than five times higher than that of phosphate-bonded high-alumina bricks. As far as its phase composition is concerned, it should be silicon carbide-mullite products, referred to as silicon mortar bricks

Silica-mold bricks were successfully trial-produced in the early 1990s. They were once called HMS high wear-resisting bricks, and their wear resistance coefficient is more than five times higher than that of phosphate-bonded high-alumina bricks. As far as its phase composition is concerned, it should be silicon carbide-mullite products, referred to as silicon mortar bricks

Lightweight refractory bricks generally refer to refractory bricks with a density less than 1.3x103kg/m3. Because of the characteristics of low density, high porosity, low thermal conductivity, good thermal insulation and some compressive strength, lightweight refractory bricks have been widely used in heat treatment equipment.

Lightweight refractory bricks generally refer to refractory bricks with a density less than 1.3x103kg/m3. Because of the characteristics of low density, high porosity, low thermal conductivity, good thermal insulation and some compressive strength, lightweight refractory bricks have been widely used in heat treatment equipment.

As a composite refractory material, magnesia-carbon refractory bricks make use of the strong slag corrosion resistance of magnesia and the high thermal conductivity and low expansion of carbon to compensate for the poor spalling resistance of magnesia. It is mainly used for steel electric furnaces.

The above-mentioned refractory bricks of different specifications and different materials have different prices. The serviceability of refractory bricks is still very long. It is resistant to high temperature and abrasion. Good refractory bricks can be used for a long time. Once and for all, the quality of the refractory bricks produced by our company is Guaranteed, detailed price issues can be consulted online, customized product solutions for you, and dedicated to serving you.

The above-mentioned refractory bricks of different specifications and different materials have different prices. The serviceability of refractory bricks is still very long. It is resistant to high temperature and abrasion. Good refractory bricks can be used for a long time. Once and for all, the quality of the refractory bricks produced by our company is Guaranteed, detailed price issues can be consulted online, customized product solutions for you, and dedicated to serving you.