- 06

- Feb

Induction heating process requirements

Induction heating process requirements

1. Workpiece through heat, such as: fasteners, standard parts, auto parts, hardware tools, rigging, hot rolling of twist drills, etc. The larger the diameter of the workpiece, the lower the frequency should be. Such as: below Φ4mm, suitable for high frequency and ultra-high frequency (100-500KHz); Φ4-16mm, suitable for high frequency (50-100KHz) )

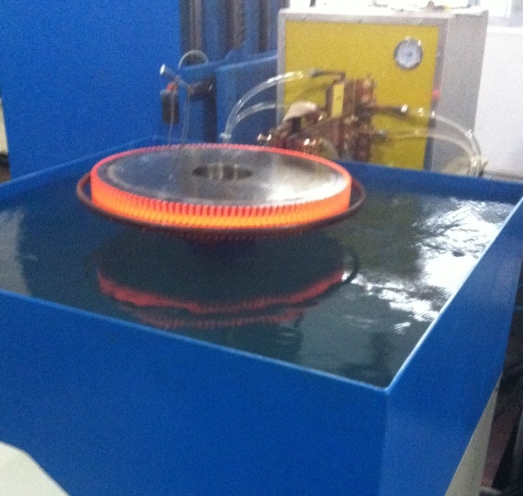

2. Heat treatment, shafts, gears, quenching and annealing of stainless steel products, etc. Take quenching as an example, the shallower the quenched layer, the higher the frequency should be, and the deeper the quenched layer, the lower the frequency should be. Such as: The quenching layer is 02.-0.8mm for 100-250KHz, ultra-high frequency, high-frequency; 1.0-1.5mm is suitable for 40-50KHz high-frequency, super-audio; mm is suitable for 8-20KHz super audio and intermediate frequency; 3.0-5.0mm is applicable for 4-8KHz intermediate frequency; 5.0-8.0mm is applicable for 2.5-4KHz intermediate frequency

3. Brazing, composite welding of different materials such as drill bits, turning tools, reamers, milling cutters, drill bits, etc., and stainless steel pot bottoms. The larger the welding volume, the more the frequency should be reduced. Take turning tool welding as an example, for example: tools below 20mm are suitable for 50-100KHz high frequency; tools above 20-30mm are suitable for 10-50KHz high frequency and super audio frequency; tools above 30mm are suitable for 1-8KHz intermediate frequency.

- Smelting gold, silver, copper, lead and other precious metals. It depends on the furnace and production efficiency. Small capacity can choose high frequency, most of them choose super audio frequency and intermediate frequency; super audio frequency can meet the general application of die casting industry, and can melt 200KG aluminum ingot per hour for general application.