- 10

- Feb

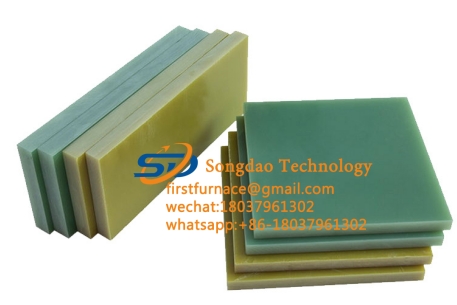

Baetsi ba boto ea insulation ea SMC ba bua ka litšobotsi tsa lisebelisoa tsa insulation

Baetsi ba boto ea insulation ea SMC ba bua ka litšobotsi tsa lisebelisoa tsa insulation

①Bongata ba polasetiki bo bobebe ka boima, bo tsitsitse lik’hemik’hale, ‘me ha bo ruse;

②Ho hanyetsa phello e ntle;

③ E na le pepenene e ntle ebile e na le khanyetso;

④Ho kenya letsoho hantle le ho theoha ha mocheso oa mocheso;

⑤Ho bōptjoa ka kakaretso, mebala e metle, litšenyehelo tse tlaase tsa ho sebetsa;

⑥Bongata ba lipolasetiki ha li na mocheso o fokolang, sekhahla se phahameng sa katoloso ea mocheso le ho chesa habonolo;

⑦ Botsitso bo bobe ba sebopeho le deformation e bonolo;

⑧Bongata ba lipolasetiki ha li na mocheso o tlase oa mocheso ‘me li fetoha brittle mocheso o tlase;

⑨ Ho bonolo ho tsofala;

⑩ Lipolasetiki tse ling li qhibiliha habonolo ka har’a lihlapolli.

Plastiki e ka aroloa ka mekhahlelo e ‘meli: thermosetting le thermoplastic. Ea pele e ke ke ea etsoa bocha le ho sebelisoa, ‘me ea morao-rao e ka hlahisoa khafetsa. Ha e le hantle ho na le mefuta e ‘meli ea meaho ea polima ea polasetiki:

Ea pele ke mohaho oa mela, ‘me motsoako oa polymer o nang le mohaho ona o bitsoa motsoako oa polymer linear;

Ea bobeli ke sebopeho sa mofuta oa ‘mele,’ me motsoako oa polymer o nang le sebopeho sena o bitsoa motsoako oa polymer oa mofuta oa ‘mele.

Li-polymers tse ling li na le liketane tse nang le makala, tse bitsoang li-polymers tsa branched, tseo e leng tsa sebopeho sa mela. Le hoja li-polymers tse ling li na le li-cross-link pakeng tsa limolek’hule, li na le li-cross-link tse fokolang, tse bitsoang sebopeho sa marang-rang ‘me ke tsa sebopeho sa’ mele. Mehaho e ‘meli e fapaneng, e bonts’ang thepa e ‘meli e fapaneng. Sebopeho sa linear (ho kenyeletsoa sebopeho sa branched) li-polymers li na le litšoaneleho tsa elasticity le polasetiki ka lebaka la ho ba teng ha limolek’hule tse ikemetseng, tse ka qhibilihang ka li-solvents, li ka qhibiliha ka ho futhumatsa, ‘me li na le boima bo tlaase le brittleness. Kaha ha ho na li-macromolecules tse ikemetseng, polymer e bōpehileng joaloka ‘mele ha e na elasticity le polasetiki, ha e khone ho qhibiliha le ho qhibiliha, empa e ka ruruha feela,’ me e na le boima bo phahameng le brittleness. Plastiki e na le meaho e ‘meli ea li-polymers, thermoplastics e entsoeng ka li-polymer tse melang, le lipolasetiki tsa thermosetting tse entsoeng ka li-polymer tse ngata.