- 09

- Mar

Bohlokoa ba tlhokomelo ea letsatsi le letsatsi ea sebōpi se qhibilihang sa induction

Bohlokoa ba tlhokomelo ea letsatsi le letsatsi ea sebōpi se qhibilihang sa induction

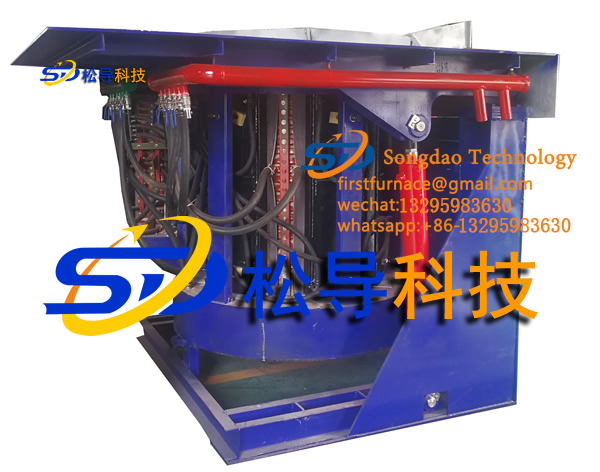

In the daily production of ho qhibiliha ha sebōpi, in addition to operating the induction melting furnace correctly and reasonably, the operating staff must also carefully and carefully do the daily maintenance of the induction melting furnace. During the operation of the induction melting furnace, due to system failure, component failure, mechanical loss or chemical corrosion, etc., it will inevitably cause abnormal operation. In order to avoid rapid damage and prevent the expansion of faults, maintenance work must be done during daily use.

Litaba tse ka sehloohong tsa tlhokomelo ea letsatsi le letsatsi ea sebōpi sa ho qhibiliha ha induction ke ho hloekisa, ho tlosa lerōle, tšireletso ea kutu le ho lokisa. Fektheri e lokela ho fana ka litokomane tse lekaneng tsa tekheniki (tse kang mekhoa ea ts’ebetso, lisebelisoa tsa tlhokomelo le lichate tsa litaelo, joalo-joalo) bakeng sa li-induction melting punch operators. Ha sebōpi se qhibilihang sa induction se hlahisoang ke Yuantuo Electromechanical se isoa ho moreki

Ka nako eo, re tla hlalosetsa bareki litaba tse lokelang ho lebisoa tlhokomelo ho tlhokomelo ea sebōpi sa ho qhibiliha sa induction, se ntlafatsang haholo bophelo ba tšebeletso ea sebōpi sa ho qhibiliha ha induction.

E le ho etsa mosebetsi o motle oa tlhokomelo, fektheri e lokela ho etsa mekhoa e sa tšoaneng ea tlhokomelo, kamehla ho boloka sebōpi se qhibilihisang induction, le ho etsa mokhoa o loketseng oa tlhokomelo bakeng sa tlhokomelo ea kamehla ho latela litaelo tsa tlhokomelo tse fanoeng ke moetsi oa sebōpi sa induction melting. Leha ho le joalo, ho sa tsotellehe hore na ke mofuta ofe oa tsamaiso ea tlhokomelo e entsoeng, boholo le likahare tsa mosebetsi o fapaneng oa tlhokomelo li lokela ho hlalosoa ka nepo, ‘me ka ho khetheha, moeli o pakeng tsa “tlhokomelo” le “tokiso” o lokela ho khetholloa. Ho seng joalo, ho bonolo ho baka ho khaola kapa ho pheta-pheta ha tlhokomelo le ho lokisoa, kapa ka lebaka la mefuta e mengata e fapaneng le e ngata haholo, mosebetsi oa sebele oo e leng oa sebaka sa tlhokomelo o thata ho o khomarela ka nako e telele, ‘me ho bonolo ho o boloka. e be semolao, mme e tla tlisa taolo ya quota le taolo e rerilweng. Litšitiso tse ngata.

Ka kakaretso, boikarabello bo ka sehloohong ba tlhokomelo ke ho theha tikoloho e ntle ea ts’ebetso bakeng sa sebōpi sa ho qhibiliha sa induction. Lintho tse ka sehloohong tsa mosebetsi oa tlhokomelo ha lia lokela ho ba tse ngata haholo, tse bonolo le tse bonolo ho li etsa, senotlolo ke ho khona ho phehella nako e telele. Likarolo tse ngata tsa tlhokomelo li ka ntle ho sebōpi sa ho qhibiliha ha induction, ‘me ha ho hlokahale ho qhaqhoa,’ me e ka phethoa ntle le ho ama ts’ebetso, ‘me ha ho hlokahale ho hlophisa nako ea tlhokomelo ka boomo. Lintho tse sebelisoang bakeng sa mosebetsi o mong le o mong oa tlhokomelo ha li ngata haholo, li bonolo ebile li bonolo.