- 28

- Oct

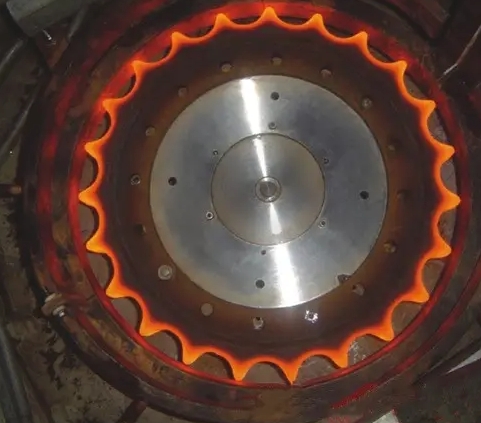

What are the types of gear quenching machines

Mefuta ea gear quenching machines

1. Outer circle quenching series: perform overall or partial quenching on the outer surface of various shafts, rods, tubes, and round parts (such as bearings, valves, etc.).

2. Letoto la ho tima selikalikoe se ka hare: etsa ho tima ka kakaretso kapa ka mokhoa o sa fellang ka har’a selikalikoe se ka hare sa liphaephe tse fapa-fapaneng le likarolo tsa mechine, tse kang li-cylinder liners, matsoho a shaft, joalo-joalo.

3. Qetella letoto la ho tima sefahleho le sefofane: etsa quenching ka kakaretso kapa e sa fellang sefahlehong sa ho qetela le karolo ea sefofane ea likarolo tsa mochini.

4. Likarolo tsa quenching tse nang le sebōpeho se khethehileng: etsa quenching ka kakaretso kapa e sa fellang holim’a karolo e itseng ea likarolo tse khethehileng.

5. Extra-large parts quenching series: perform overall or partial quenching on large and heavy-weight parts, such as marine gears, dam sluice rails, large oil pipelines, etc.

- Die surface quenching series: Die surface induction quenching machine tool is a CNC process equipment suitable for heat treatment of large automobile cover molds and large non-circular space curved parts.