- 03

- Sep

Moea o pholileng oa indasteri

Lintlha tsa moea o pholileng o monyane:

Likarolo tsa pholileng e nyane ea moea:

1. Liindasteri tse pholileng tsa moea li arotsoe ka mefuta e ‘meli: mofuta o tloaelehileng le mofuta o tlase oa mocheso

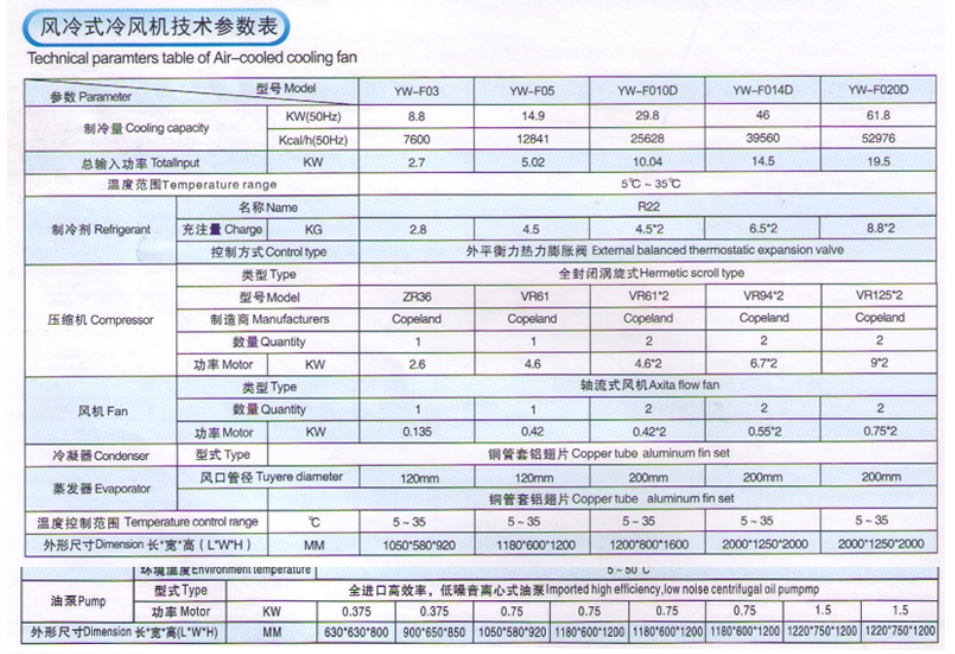

1. Mocheso oa moea o pholileng oa moea o pholileng oa indasteri ke: 5 ℃ -10 ℃, le bophara ba phala ea sehokelo: 100/250, e ka ikhethileng ho latela litlhoko tsa moreki.

2. Mocheso oa mocheso oa mocheso o tlase oa mocheso ke: -15 ℃ -0 ℃, le bophara ba phala ea sehokelo: 100/250, e ka ikhethileng ho latela litlhoko tsa moreki.

2. Likarolo tsa lihlahisoa tse pholileng tsa moea

1. Sisteme e ntlafalitsoe ebile e entsoe. Lisebelisoa li na le karolelano e phahameng ea ts’ebeliso ea matla le moralo o nang le patent e nang le sehlahisoa se selelele sa tlhahiso ea moea. Ha e bapisoa le lihlahisoa tse ts’oanang, e na le litšobotsi tsa tšebeliso e tlase ea matla le sebaka se selelele sa phepelo ea moea;

2. Ho na le mekhoa e fapaneng ea ho theola, e nang le nako e khuts’oane ea ho theola le phello e ntle. Mofuta oa phepelo ea motlakase o nang le ts’ireletso e habeli ea mocheso o ka fokotsa ho phahama ha mocheso ho bakoang ke ho senya le ho boloka ts’ebeliso ea matla ea ho senya;

3. Sebopeho sa khetla e sa keneleng metsi le e thibelang likokoana-hloko, e sebelisa theknoloji e sirelletsang khase e sireletsang khase, bohloeki bo phahameng tsamaisong, tlhophiso ea litsebi tsa phapanyetsano ea mocheso ho fokotsa ho hanyetsa moea ka lehlakoreng, ho hanyetsa mocheso o monyane, le ts’ebetso e phahameng ea phetisetso ea mocheso;

4. Ho sebelisoa motlakase o khethehileng oa fan, e leng bopaki ba mongobo, bo sa keneng mocheso o tlase, bophahamo ba moea bo boholo, lerata le tlase, ts’ebetso e tsitsitseng le e tšepahalang, ‘me mocheso oa sehatsetsi ke -25 ℃ ~ + 10 ℃, e nang le mefuta e mengata. ea likopo.

5. Libaka tsa ts’ebeliso li kenyelletsa: tsidifatso ea mosebetsi, ho futhumatsa kotopo, laser, indasteri ea lik’hemik’hale, electroplating oxidation, lisebelisoa tse nepahetseng tsa mi, enke, khatiso, ho etsa pampiri, lisebelisoa tsa tšepe, ho lahla, ho enta ka ente le indasteri ea blister, ho futhumatsa lijo, indasteri ea meriana, boto ea potoloho ea elektroniki, leqhubu soldering Reflow soldering, kalafo sebaka, tjheseletsa le ho itšeha, kalafo holim, theknoloji khalase, sebetsa mabenyane, letlalo, aquaculture

6. Sistimi e laolang mocheso ka botlalo, yuniti e etselitsoe ho sebetsa ntle le ho koala lihora tse 24.

7. E ka etsoa le ho ikamahanya le maemo ho latela litlhoko tsa moreki.