- 31

- May

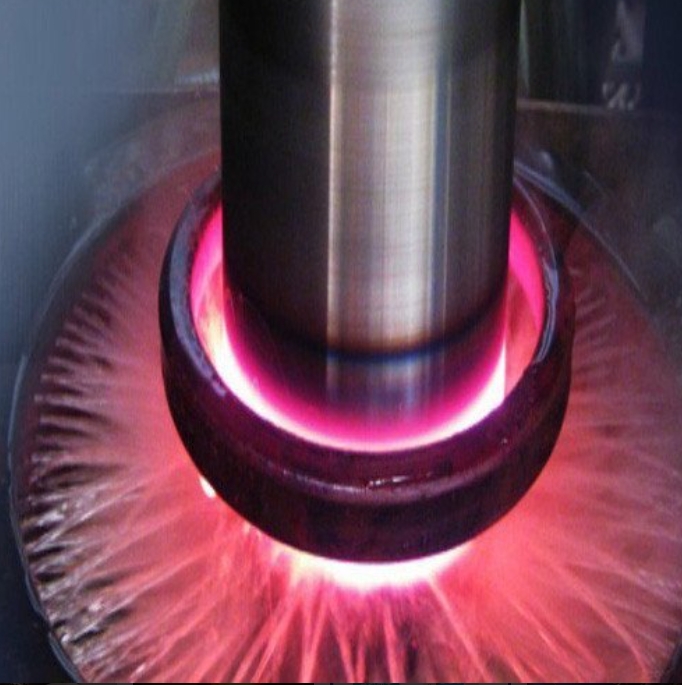

Melemo ea mochini o futhumatsang o phahameng oa induction ka holim’a ho tima lisebelisoa tsa tšepe

Melemo ea mochine oa ho futhumatsa oa motlakase o phahameng ka holim’a quenching ea tšepe workpieces

Ho tima holim’a lisebelisoa tsa tšepe ka mochini o futhumatsang oa maqhubu a phahameng ho bapisoa le mekhoa e tloaelehileng le ea setso ea ho futhumatsa le ho tima: ho tima lelakabe ho futhumatsa holim’a mollo, ho tima metsi a futhumetseng ka holim’a metsi, ho tima metsi a futhumetseng a electrolyte, ho tima laser ho futhumatsa holim’a metsi, ho tima mocheso oa electron beam. , joalo-joalo. Ka tlase, kakaretso e na le melemo e latelang:

1. Lebelo la ho futhumatsa le potlakile ka ho fetisisa, le ka eketsang mocheso oa mocheso oa phetoho ea workpiece A le ho khutsufatsa nako ea phetoho.

2. Ka mor’a ho tima, karolo e ka holimo ea workpiece e ka fumana martensite e ntle ka ho fetisisa ea cryptocrystalline, ‘me boima bo phahame hanyenyane (2-3HRC). Mochini o futhumatsang oa maqhubu a phahameng a phahameng o nang le brittleness e tlase le matla a holimo a mokhathala.

3. Li-workpieces tse tšoaroang ke ts’ebetso ena ha li bonolo ho oxidized le decarburized, esita le li-workpieces tse ling li ka bokelloa ka ho toba ‘me tsa sebelisoa ka mor’a phekolo.

- Lera le thata le tebile, le bonolo ho le laola le ho sebetsa, ho bonolo ho elelloa mokhoa oa ho sebetsa le othomathike.