- 11

- Apr

Castable for induction heating furnace

Castable for induction heating furnace

Castable series refractory materials for induction heating furnace Description: This refractory product has a compact structure, excellent high temperature performance, good thermal shock stability and peeling resistance, and convenient construction. It is mainly used for the insulation lining of induction heating furnaces. , Working lining, etc. or directly poured into prefabricated parts for use.

jentre

The induction heating furnace is a thermal equipment used to heat billets or small steel ingots during steel rolling or forging. The furnace body of the induction heating furnace is composed of the furnace wall, the furnace bottom and the furnace top. Its temperature is not high, generally below 1400 ℃. For continuous or annular induction heating furnaces, the furnace temperature of each part is basically constant. It can be divided into three zones of low temperature, medium temperature and high temperature, which are respectively called preheating zone, heating zone and soaking zone. They are 800~900℃, 1150~1200℃, and 1200~1300℃ respectively. The damage of the furnace lining is mainly due to temperature fluctuations caused by intermittent operation and shutdown of the furnace, which leads to deformation and thermal spalling of the furnace lining. The damage to the bottom of the furnace and the root of the furnace wall is mainly caused by the chemical reaction between the molten iron oxide slag and the bricks. Therefore, different refractory materials should be selected according to the different conditions of different parts.

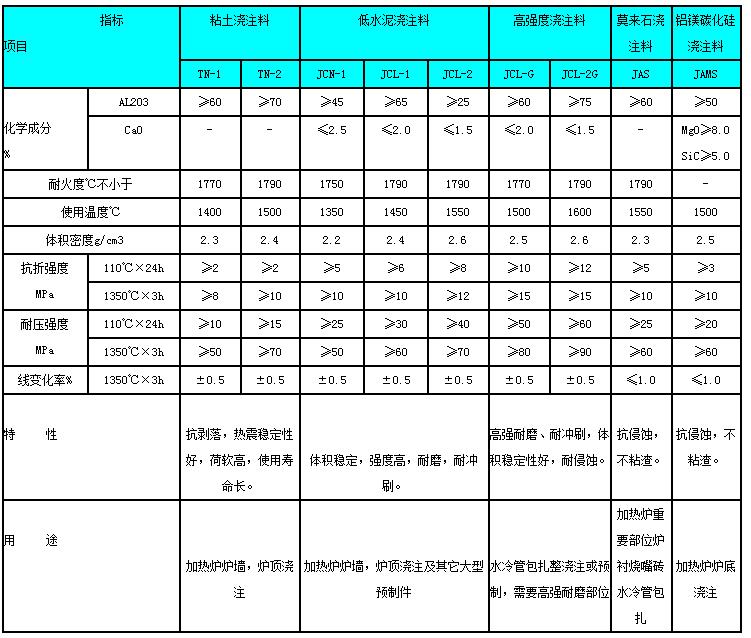

Indéks téknis: