- 24

- Jan

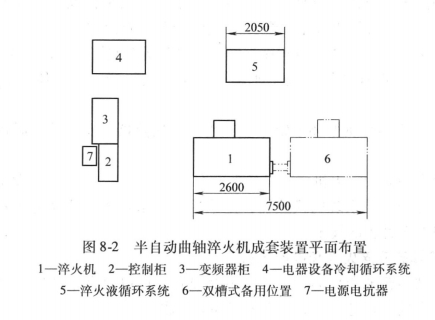

Complete equipment for crankshaft semi-automatic quenching machine

Complete equipment for crankshaft semi-automatic quenching machine

The total length of the crankshaft is within 1500mm, the journal diameter is within 90mm, the journal is quenched or the journal and the fillet are quenched together.

1) Thyristor or transistor IGBT intermediate frequency power supply (160~225kW, 8~10kHz).

2) Semi-automatic immersion quenching machine tool, including a star bracket with four crankshafts in the quenching tank, capacitors and quenching transformers, inductors and quick-change chucks, power distributors (for round corner quenching) , Required parts).

3) Electrical equipment cooling water circulation system, including heat exchanger, multi-stage water pump (0.8MPa, 10m3/h), plastic soft water tank (capacity In?) and monitored temperature, pressure instruments and actuators, heat exchanger capacity reference value 50000kcal/h (58kW) o

4) Cooling the quenching fluid circulation system, the quenching fluid tank is the bed part of the quenching machine tool, the quenching fluid pump flow is 20m3/h, 0.7MPa, and the reference value of the heat exchanger capacity is 35000kcal/h (41kW).

The plan layout of the complete set of semi-automatic crankshaft quenching machine is shown in Figure 8-2. This set of equipment does not include the circulating water cooling system to save industrial water.