- 27

- Oct

In which processing technology are induction heating equipment widely used?

In which processing technology are ప్రేరణ తాపన పరికరాలు widely used?

1. Heat treatment process

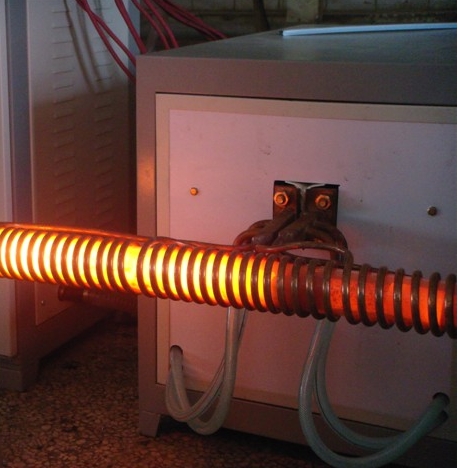

According to a large number of survey data, induction heating equipment is widely used in heat treatment processes, such as surface quenching of gears, shafts, crankshafts and other workpieces. Induction heating equipment will output an alternating current with a suitable frequency for quenching the surface of various workpieces. Generally, workpieces such as high carbon steel and cast iron are processed by induction heating. This heat treatment process is efficient and fast.

2. Hot assembly process

According to a large number of research data, induction heating equipment can also be widely used in thermal assembly processes. For example, some metal parts with a large amount of hot tenon are usually heated by induction heating facilities. When the diameter of the pad is expanded to the corresponding standard, the assembly can be carried out while it is hot. In this way, it can ensure that the metal parts have a high The connection strength can also ensure that the difficulty of disassembling metal parts is greatly reduced.

3. Welding process

It is understood that many industries nowadays often need to use induction heating equipment during welding. The so-called welding process refers to the use of high heat and high pressure to connect metals or other processed materials by hot melt connection. Induction heating power supply facilities can provide an energy source for this hot melt connection, thereby making the hot melt welding process smoother.

The application of induction heating equipment to process metal materials not only has higher efficiency and higher speed, but also has excellent environmental performance. This has prompted people’s recognition of induction heating equipment to increase year by year. In addition to being particularly suitable for heat treatment processes and hot assembly processes, induction heating equipment is also particularly suitable for hot melt welding and equivalent types of processing processes.