- 08

- Sep

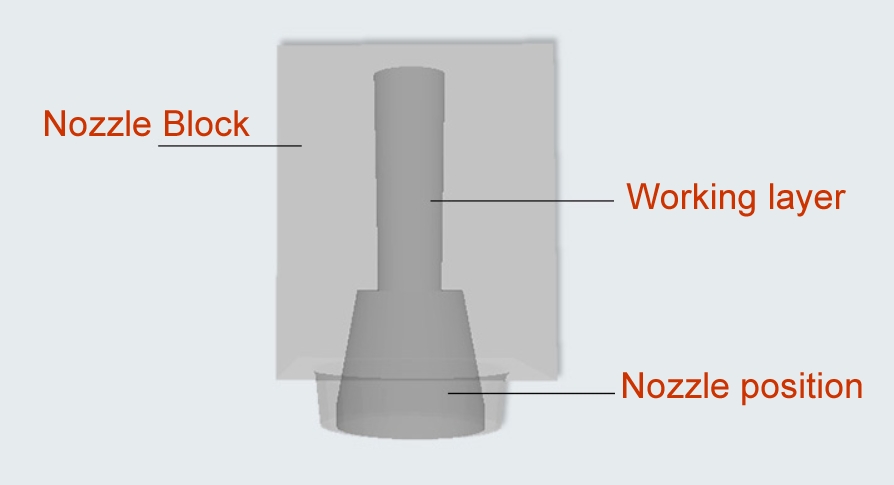

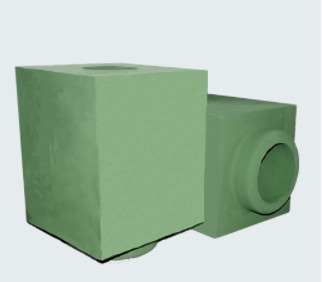

Ladle nozzle block

Ladle nozzle block

This product is made of high-purity raw materials, formed by vibration casting, and baked at low temperature. It has the advantages of high thermal strength, good thermal shock resistance, erosion resistance and erosion resistance, and hot repair. It is used in Shagang, Huaigang and Henggang Used by other units, it has been well received by customers.

Main raw material: corundum Al₂O₃:80-94% MgO:2-5% Cr₂O₃:0-3%

అంతర్గత నిర్మాణం

Technical parameters of ladle nozzle block

| అంశం / గ్రేడ్ | Chrome corundum | కురువిందరాయి | Chromium corundum mullite |

| Al2O3 (%) | ≥90 | ≥92 | ≥80 |

| MgO (%) | ≤2.0 | ≤2.0 | ≤2.0 |

| Cr2O3(%) | ≥2.0 | / | ≥1.5 |

| Bulk density (g/cm³) | ≥2.95 | ≥2.95 | ≥2.90 |

| Compressive strength at room temperature (MPa) | ≥60 | ≥50 | ≥50 |

Patented formula

Patented, unique formula, anti-scouring, anti-expanding, longer service life.

Hot patchable

The seat brick repairing material specially developed for the nozzle seat brick and the breathable brick seat brick can be hot repaired, which can greatly extend the service life and give you more peace of mind

Fully customized

The shape and chromium oxide content are completely customized according to customer requirements. To meet the different needs of different customers.