- 18

- Apr

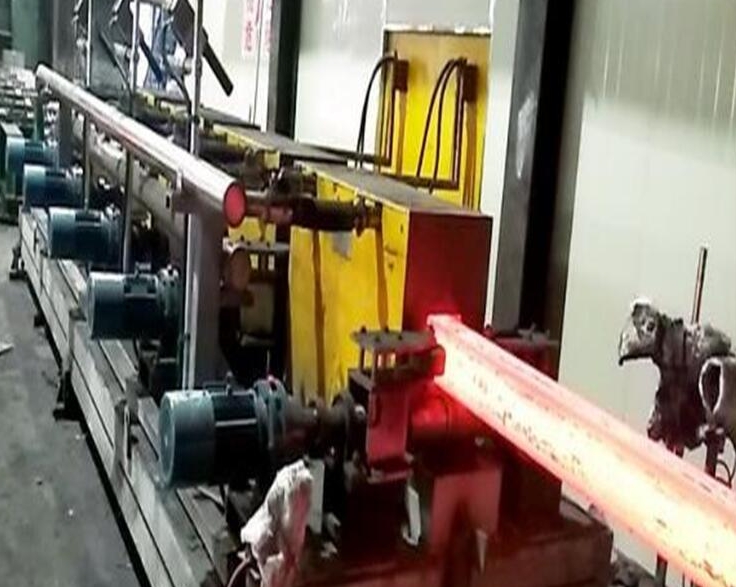

Copper bar forging heating equipment

Copper bar forging heating equipment

The copper bar forging heating equipment is non-standard induction heating equipment. According to the copper bar heating and forging process parameters, such as copper bar specifications, weight, heating temperature, production efficiency and other special requirements, it is equipped with PLC control system, automatic feeding system, temperature measurement System, etc., can realize the intelligent production of copper bar forging and heating equipment, and meet the needs of intelligent factory construction.

1. Parameters of copper bar forging heating equipment:

1. Blank size: Φ254mmX388 (Φ150-Φ305)

2. Material: alloy copper

3. Temperatura ng pag-init: 1200 ℃

4. Production rhythm: 55 seconds/root

5. Timbang: 53KG

2. Composition of copper bar forging heating equipment:

1. 1250KWKW/300Hz thyristor variable frequency induction heating power supply

2. Furnace frame (including capacitor bank, waterway and circuit)

3. Sensor: GTR furnace body

4. Connecting cables/copper bars (power supply to furnace body)

5. Automatically lift timing feeding device

6. Sistema ng pagsukat ng temperatura ng infrared

7. In and out conveying device

8. PLC console (PLC control)

3. Copper bar forging heating equipment Working process:

The mechanical action of the copper bar forging heating equipment is controlled by the infrared temperature measurement PLC to push the material regularly.

Manually place the material on the storage platform in front of the furnace → the chain lifting mechanism automatically refills the material → heating in the furnace → infrared temperature measurement → rapid discharge

4. Mechanical part of copper rod forging heating equipment:

The mechanical part of the copper bar forging heating equipment is composed of: furnace frame, feeding mechanism, feeding mechanism, discharging mechanism, etc. Its action setting and heating rhythm are controlled by PLC.

1. Feeding mechanism The feeding mechanism is completed by the storage table, the V-shaped groove in front of the furnace and the conveying device. The discharge port is equipped with a roller discharge mechanism, so that the material will not collide with the furnace body outlet.

- The furnace frame is a section steel welding component, which contains water circuit, electric circuit, gas circuit components, capacitor tank copper busbar, etc. Above is the sensor.