- 14

- Oct

Troubleshooting method for water temperature alarm of quenching machine tool equipment

Troubleshooting method for water temperature alarm of quenching machine tool equipment

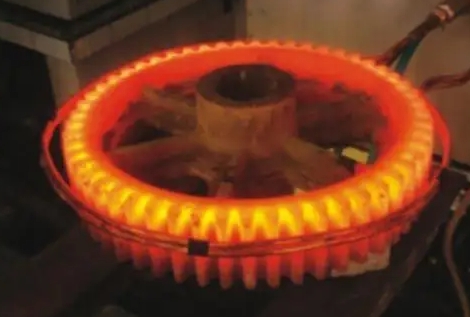

After the quenching machine tool is started for a long time, there will be a water temperature alarm phenomenon during the operation: check the water temperature of the pool, and replace the cooling water if the water temperature in the pool is too high.

After working for a period of time or a few minutes, the water temperature will alarm, and the quenching machine will continue to operate after a period of shutdown. Frequent alarms: Check the cooling water pipes inside the main control cabinet to see if there is any blockage. In the case of long-term use, the cooling water must be kept clean. Prevent debris in the water from blocking the water pipe to cause water temperature alarms or other equipment failures. The method of removing the blockage of the water pipes of the quenching machine tool: remove all the water pipes from the direction of the water outlet inside the control cabinet, and use an air compressor or other blowing equipment to clean them one by one to ensure that all the water pipes are dredged.

After confirming that all the water pipes are unblocked, the equipment still alarms, it is very likely that the quenching machine has severe scaling and needs to be descaled. A descaling agent can be purchased in the market for descaling. Scale removal method: According to the size of the quenching machine, about 25 kg of water can be mixed with 1.5-2 kg of descaling agent, and the water pump can be circulated for 30 minutes, then replaced with clean water and circulated for 30 minutes.

Sometimes it alarms and sometimes stops: the pressure of the water pump of the quenching machine tool is unstable. If the pressure of the water pump is unstable, air bubbles easily occur in the water pipe. Because the position of the three-phase bridge cooling water box is relatively high, the air bubbles will go up and part of the cooling water box will be empty, so This part is simply because the water temperature is too high to cause the water temperature alarm maintenance of the quenching machine tool. Solution: just increase the pressure of the pump.