- 05

- Oct

Ball flat steel 350KW/4KHZ quenching equipment

Ball flat steel 350KW/4KHZ quenching equipment

A, 350KW/4KHZ quenching equipment process parameters:

1. Quenching temperature: 880 ° C

2. Quenching depth: 3-5mm

3. Workpiece diameter: 1000 mm, 800 mm, 460 mm, 370 mm

4. Bending degree: the flatness of the flat steel is not more than 3mm per meter, and the total bending is not more than 0.3% of the total length.

B, ball flat steel heating system parameters determination

1. Calculation of the total power for heating

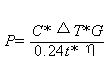

Calculate the required power (ie the average power of the sensor) P using the following formula:

Where: C—specific heat of the billet (Kcal/Kg*°C) C=0.168

T — temperature rise of the billet (°C) eg: quenching temperature 890 ° C, ΔT = 890 ° C

G—weight of the billet (Kg)

t — heating time ( S )

Η—total efficiency, take 35%

According to the above calculation, considering that the overall efficiency of the quenching transformer and the single-turn inductor is relatively low, 30% is calculated, and the total heating power is set to 350 KW.

2, 350KW / 4KHZ quenching equipment heating frequency selection

The choice of the quenching heating frequency depends mainly on the relationship between the thickness of the workpiece and the depth of penetration of the current generated by the heating frequency. If the frequency is too low, the heating efficiency will be significantly reduced. If the frequency is too high, the heating depth will be insufficient, and the temperature on the surface and inside of the workpiece will be uneven. For ball flat steel, which is very irregular in shape, our company recommends using a heating frequency of 6KHz. For the web part, the current penetration depth can be directly heated to the center position. For the ball end part, the extension of the inductor is used to extend the heating time. Through the heat conduction for a certain period of time, when the workpiece moves to the spraying position, the internal and external temperatures are consistent through heat conduction, so that the entire workpiece is quenched uniformly.

3. Transfer speed of workpiece of 350KW/4KHZ quenching equipment:

1000 mm 1 m / 20 min

800 mm 1 m / 930 seconds

460 mm 1 m / 539 seconds

370 mm 1 m / 426 seconds

C, 350KW/4KHZ quenching equipment IF power supply selection

1, circuit form

The circuit adopts 6-pulse rectification mode, and the incoming line voltage is 380V. The inverter adopts double-bridge inverter, and the inverter thyristor adopts double series. .

3, the performance characteristics of the intermediate frequency power supply

3.1, the control system is fully digital, no relay control

3.2 Unique sweeping start mode with 100% startup success rate

3.3 Regulator with fast response characteristics

3.4 Excellent impact load resistance

3.5 Improve reliable protection

3.6 Advanced phase sequence self-identification function

3.7 Rich external control interface

3.8 optical isolation pulse output

3.9 Commissioning and maintenance is simple and convenient

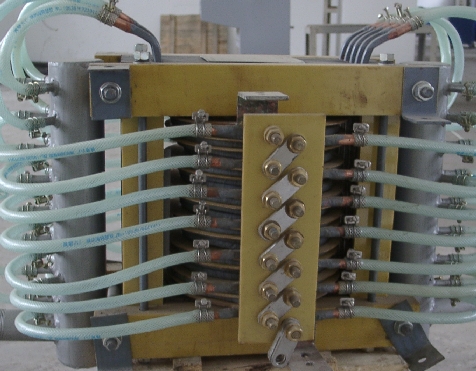

D, 350KW/4KHZ quenching equipment quenching transformer selection

In order to achieve the matching of the intermediate frequency resonance, a quenching transformer must be connected before heating the inductor.

The PR type quenching transformer is composed of a core and a primary secondary winding. The iron core is made up of 0.2-0.3mm thick high-magnetic imported silicon steel sheets (3K pieces). The iron core cooling adopts a water jacket type structure, and the transformer has strong overload capability, which is especially suitable for long-term continuous operation. The winding coils are wound in an overlapping manner, and the turns ratio is changed more, and the original paying side can be arbitrarily combined into odd-even ratios according to needs, and the load adaptability is strong. The specific parameters are as follows:

| model | capacity | Matching intermediate frequency power | Primary side ratio | Secondary side ratio | Adaptive frequency |

| PR-1500 | 1500KVA | 250KW | 25~7 | 1 to 2 | 1~8KHz |