- 13

- Nov

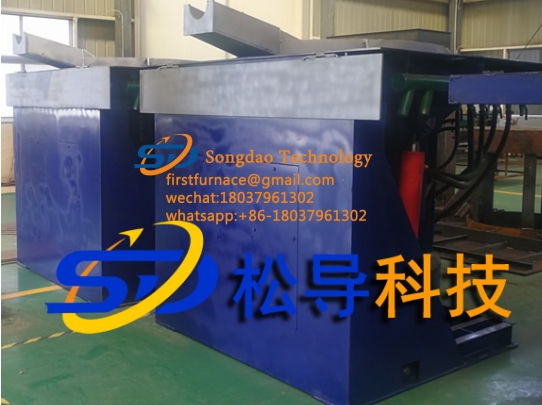

Transformer configuration of 5 ton intermediate frequency steelmaking furnace

Transformer configuration of 5 ton intermediate frequency steelmaking furnace

Intermediate frequency steelmaking furnace is different from other equipment in the configuration of transformers. Electricity is the heart of the intermediate frequency steelmaking furnace. The instantaneous current and large fluctuations of the intermediate frequency steelmaking furnace during the smelting process require the transformer to be a special transformer.

Choose low-loss transformers. The medium-frequency steelmaking furnace uses high load for a long time, and the transformer’s own loss directly affects the power consumption per ton.

Rated capacity t 5.0 Liquid steel / molten iron

Maximum capacity t 5.5 liquid steel/hot metal

Working temperature ℃ 1600

Maximum working temperature ℃ 1750

Lining thickness mm 150

Induction coil inner diameter φ mm 1410

Induction coil height mm 1620

Transformer capacity KVA 3150

Transformer primary voltage KV 10

Transformer secondary voltage V 900 12-pulse dual output

Rated power of intermediate frequency power supply KW 3000 12-pulse dual input

Rated input current A 2280

DC voltage V 1200

DC current A 1500

Conversion efficiency% 96

Startup success rate% 100

The highest output voltage of the intermediate frequency power supply V 1700

Rated operating frequency Hz 350

Power conversion efficiency% 96

Startup success rate% 100

Melting rate (heating up to 1600℃) T/h 4.96 The time used to melt one furnace is related to the charging

Melting power consumption (heating to 1600℃) KW.h/T less than 530

冷卻水系統

Cooling water circulation flow T/h 80

Water supply pressure Mpa 0.25-0.35

Inlet water temperature ℃ 5-35

Outlet water temperature ℃ <55

https://songdaokeji.cn/category/products/induction-melting-furnace

https://songdaokeji.cn/category/blog/induction-melting-furnace-related-information

電話:8618037961302