- 12

- Apr

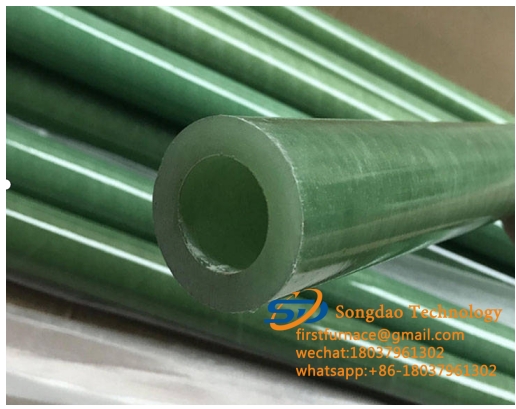

Iimpawu zokusetyenziswa kombhobho we-epoxy

Iimpawu zokusetyenziswa kombhobho we-epoxy

Iimpawu zokusetyenziswa kombhobho we-epoxy:

1. Iifomu ezahlukeneyo. Uluhlu olubanzi lweereyini, ii-arhente zokunyanga, kunye neenkqubo zokulungisa ziyafumaneka ukuze zilungele zonke iimfuno zefomu yesicelo, ukusuka kwi-viscosity ephantsi kakhulu ukuya kwindawo ephezulu yokunyibilika.

2. Kulula ukunyanga. Ngokusebenzisa iindlela ezahlukeneyo zokunyanga, iinkqubo ze-epoxy resin zinokunyangeka kuluhlu lobushushu obuphakathi kwe-0 ukuya kwi-180 °C.

3. Ukubambelela okuqinileyo. Ubukho bepolar hydroxyl kunye neebhondi ze-ether ezikwitsheyini yemolekyuli ye-epoxy resin [1] iyenza ibenoncanyelo oluphezulu kwizinto ezahlukeneyo. Iireyini ze-epoxy zine-shrinkage ephantsi xa zinyangwa kwaye zenza uxinzelelo oluncinci lwangaphakathi, olukwanegalelo ekuphuculeni amandla okubambelela.

4. Ukuncipha okuphantsi. Ukusabela kwe-epoxy resin kunye ne-agent ephilisayo esetyenzisiweyo iqhutyelwa ngokuphendula ngokuthe ngqo kongezwa okanye i-polymerization yokuvula i-ring yamaqela e-epoxy kwi-molecule ye-resin, ngaphandle kokukhululwa kwamanzi okanye ezinye iimveliso eziguqukayo. Babonisa i-shrinkage ephantsi kakhulu (ngaphantsi kwe-2%) ngexesha lokunyanga xa kuthelekiswa ne-unsaturated polyester resins kunye ne-phenolic resins.

5. Iipropati zoomatshini. Inkqubo ye-epoxy resin ephilisiweyo ineempawu ezintle kakhulu zoomatshini.