- 27

- Jul

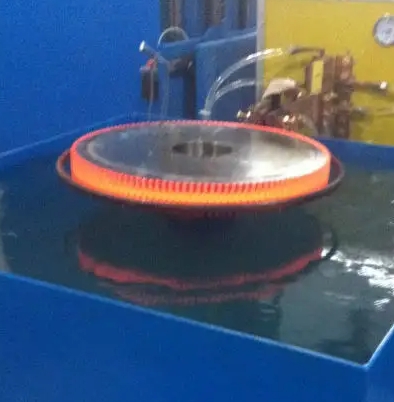

Application of high frequency heating machine quenching equipment

- 28

- Jul

- 27

- Jul

Ukusetyenziswa kwe ukucima umatshini wokufudumeza amaza aphezulu izixhobo

The frequency is about 30KHZ, the smaller one can quench high-precision small shafts with a diameter of about 10mm, and the quenching layer can be kept within 1.5mm.

1. Surface, inner hole, partial or overall quenching of all kinds of hardware tools, electric, hydraulic, steam-driven components, auto parts, motorcycle parts and other mechanical metal parts. Such as hammers, knives, scissors, pliers and various shafts, cams, sprockets, gears, valves, ball studs, etc., as well as large machine tool accessories and quenching of ductile iron, many domestic manufacturers of sprockets and gears have adopted this Company equipment for heat treatment.

2. High-frequency quenching heat treatment of various automobile and motorcycle parts, such as: crankshaft, connecting rod, piston pin, camshaft, valve, various gears in the gearbox, various forks, various spline shafts, transmission half shafts , Various small shaft crank pins, various rocker arms, rocker arm shafts and other high-frequency quenching heat treatment.

3. High-frequency quenching heat treatment of hardware tools, such as vices, hammers, strong pliers, wrenches.

4. Quenching of hydraulic components such as: the plunger of the plunger pump, the rotor of the rotor pump, the reversing shaft on various valves, the gear of the gear pump, etc. are high-frequency quenching.

5. High-frequency quenching treatment of various power tool gear shafts.

6. Izixhobo ezahlukahlukeneyo zomthi, ezifana nezi: izembe, iiplani kunye nolunye unyango lobushushu.