- 22

- Aug

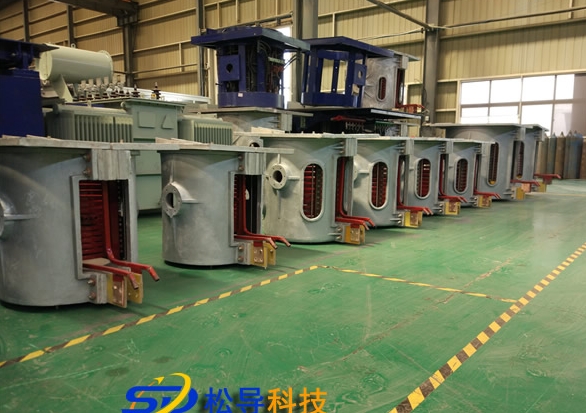

Esona sizathu siphambili sokutshisa i-coil yokunyibilika kwesithando se-induction

Esona sizathu siphambili sokutshiswa kwe ukuchithwa kwesithando somlilo coil

Isizathu esona sizathu sokuba i-coil ihlahleni: amandla okukhusela i-coil ayilungile. Ipeyinti ye-insulating esetyenziswe kumphezulu we-coil frequency frequency idla ngokuba yipeyinti ye-insulating yesiqhelo. Ngenxa yeemeko ezinzima zokusebenza kwesithando sombane, i-peeling kunye ne-carbonization yepeyinti ye-insulating yafunyaniswa inzulu kwindawo, enokuthi ibangelwa ezi zizathu zilandelayo:

a) Ekupheleni komkhankaso wesithando somlilo, i-refractory material kwisithando somlilo iba yincinci, ukushisa okugqithisiweyo kwi-coil kwanda, kwaye ubushushu be-ambient yekhoyili buba phezulu. Ipeyinti ye-insulating yesiqhelo ayinayo ukumelana nokushisa okuphezulu kwaye kulula ukuba i-carbonized.

b) Xa i-furnace yombane ibetha, i-slag yensimbi itshiza kwi-coil yesithando somlilo, kunye nepeyinti ekhuselayo ebusweni bekhoyili itshatyalaliswa ngokuthe ngqo.

c) I-seapage yensimbi etyhidiweyo evela kwi-refractory material ithinta ngokuthe ngqo indawo yekhoyili kwaye ngokukhawuleza itshabalalise i-insulating layer phezu kobuso bekhoyili. Kwaye ngenxa yokuba i-varnish yangoku ye-insulating ayinakho ukumelana nokushisa okuphezulu, ayikwazi ukukhusela i-coil. Intsimbi etyhidiweyo enobushushu obuphezulu obuphezulu inokutshisa ngokulula ikhoyili ngqo. Iziva ezixhaphakileyo ezinzulu kwikhoyili nazo ziyangqina oku.

d) Imeko yendawo apho ikhoyili ibekwe khona inomhlwa kakhulu, kwaye ipeyinti eqhelekileyo yokugquma ayinakuxhathisa ngokufanelekileyo umhlwa, kwaye kulula ukonakala kwaye siwe kwaye iphulukane namandla ayo okugquma.