- 11

- Feb

Ziziphi iintlobo zezitena eziphikisayo?

Zithini iindidi ze izitena ezikhanyelayo?

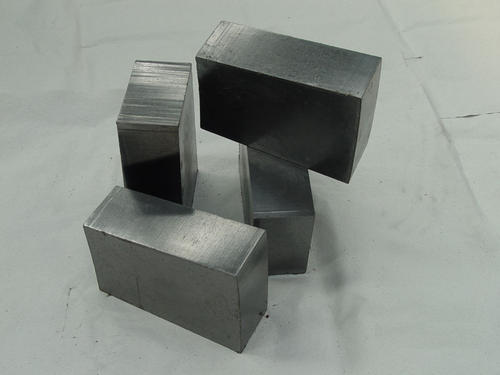

Izitena eziphikisayo zihlobo ezahlukeneyo kunye nezihlandlo zokusetyenziswa. Izitena eziphikisayo luhlobo lwezinto eziphikisayo kunye nokusebenza kweendleko eziphezulu. Abasebenzisi banokukhetha izitena ezifanelekileyo eziphikisayo ngokobukhulu kunye neenkcukacha zemveliso kunye nezixhobo ezahlukeneyo. Zeziphi iintsebenzo zeentlobo ngeentlobo, makhe ndikwazise kuzo apha ngezantsi.

Inkampani yethu inezitena ezilahlayo, izitena ezikhanyelayo ze-mullite ezikhanyelayo, izitena ezilahlayo zokutshisa i-carbon, izitena ezikhanyelayo ze-silicon-moon, izitena ezikhanyelayo ezikhanyayo, kunye nezitena ze-carbon refractory ze-magnesia.

I-Mullite lightweight refractory izitena zizinto eziphezulu ze-alumina eziphikisayo kunye ne-mullite njengenqanaba lekristale eliphambili. Ngokuqhelekileyo, umxholo we-alumina uphakathi kwe-65% kunye ne-75%. Ukongeza kwi-mullite, ukubunjwa kwamaminerali kunye ne-alumina ephantsi kuqulethe ixabiso elincinci leglasi kunye ne-cristobalite; umxholo ophezulu we-alumina uqulethe ixabiso elincinci le-corundum

Ukuveliswa kweemveliso zekhabhoni ikakhulu kusetyenziswa amaziko okutshisa okuphambili kunye nesekondari kunye neegrafu, ezibizwa ngokuba ziimveliso zekhabhoni zokutshisa iziko. Iimveliso zekhabhoni ezitshisa iziko zinokwahlulwa zibe zizitovu zebhetshi, iziko eziqhubekayo, iziko legumbi, iitoni zokutshiza, izitofu zetonela, iitoni ezijikelezayo okanye izitofu zokuxhathisa ngokwesakhiwo kunye neendlela zokusebenza.

Izitena ze-silica-mold zaveliswa ngempumelelo ekuqaleni koo-1990. Zazikhe zabizwa ngokuba zizitena ezixhathisa ukunxitywa kwe-HMS, kwaye i-coefficient yabo yokumelana nokunxiba ingaphezulu ngokuphindwe kahlanu kunezitena ze-phosphate-bond high-alumina. Ngokubhekiselele ekubunjweni kwesigaba sayo, kufuneka ibe yimveliso ye-silicon carbide-mullite, ekubhekiselwa kuyo njengezitena zodaka lwe-silicon.

Izitena ze-silica-mold zaveliswa ngempumelelo ekuqaleni koo-1990. Zazikhe zabizwa ngokuba zizitena ezixhathisa ukunxitywa kwe-HMS, kwaye i-coefficient yabo yokumelana nokunxiba ingaphezulu ngokuphindwe kahlanu kunezitena ze-phosphate-bond high-alumina. Ngokubhekiselele ekubunjweni kwesigaba sayo, kufuneka ibe yimveliso ye-silicon carbide-mullite, ekubhekiselwa kuyo njengezitena zodaka lwe-silicon.

Izitena ezikhanyelayo ezilula zibhekisela kwizitena eziphikisayo ezinobunzima obungaphantsi kwe-1.3x103kg / m3. Ngenxa yeempawu zokuxinana okuphantsi, i-porosity ephezulu, i-conductivity ephantsi ye-thermal, i-insulation efanelekileyo ye-thermal kunye namandla athile acinezelayo, izitena ezikhanyelayo ezilula zisetyenziswe ngokubanzi kwizixhobo zonyango lokushisa.

Izitena ezikhanyelayo ezilula zibhekisela kwizitena eziphikisayo ezinobunzima obungaphantsi kwe-1.3x103kg / m3. Ngenxa yeempawu zokuxinana okuphantsi, i-porosity ephezulu, i-conductivity ephantsi ye-thermal, i-insulation efanelekileyo ye-thermal kunye namandla athile acinezelayo, izitena ezikhanyelayo ezilula zisetyenziswe ngokubanzi kwizixhobo zonyango lokushisa.

Njengemathiriyeli edityanisiweyo ephikisayo, izitena ze-magnesia-carbon refractory zisebenzisa i-slag corrosion resistance resistance ye-magnesia kunye ne-thermal conductivity ephezulu kunye nokwandiswa okuphantsi kwekhabhoni ukuhlawulela ukunganyangeki kwe-spalling ye-magnesia. Isetyenziselwa ikakhulu kwiziko zombane zentsimbi.

Izitena ezichasayo ezikhankanywe ngasentla zenkcazo eyahlukeneyo kunye nezixhobo ezahlukeneyo zinamaxabiso ahlukeneyo. Ukusebenza kwezitena eziphikisayo kusekude kakhulu. Iyakwazi ukumelana nobushushu obuphezulu kunye ne-abrasion. Izitena ezilungileyo zokuphikisa zingasetyenziselwa ixesha elide. Kanye kanye, umgangatho wezitena ezichasayo eziveliswe yinkampani yethu ziqinisekisiwe, imiba yexabiso eneenkcukacha inokuboniswa kwi-intanethi, izisombululo zemveliso ezilungiselelwe wena, kwaye zinikezelwe ekukhonzeni.

Izitena ezichasayo ezikhankanywe ngasentla zenkcazo eyahlukeneyo kunye nezixhobo ezahlukeneyo zinamaxabiso ahlukeneyo. Ukusebenza kwezitena eziphikisayo kusekude kakhulu. Iyakwazi ukumelana nobushushu obuphezulu kunye ne-abrasion. Izitena ezilungileyo zokuphikisa zingasetyenziselwa ixesha elide. Kanye kanye, umgangatho wezitena ezichasayo eziveliswe yinkampani yethu ziqinisekisiwe, imiba yexabiso eneenkcukacha inokuboniswa kwi-intanethi, izisombululo zemveliso ezilungiselelwe wena, kwaye zinikezelwe ekukhonzeni.