- 16

- Jun

Ingxenye eyinhloko yesithando somlilo se-induction, izici zokuphepha ze-thyristor

Ingxenye eyinhloko ye- ukuchithwa kwesithando somlilo, izici zokuphepha ze-thyristor

I-thyristor yesithando somlilo sokuncibilika kwe-induction iwumgogodla wokunikezwa kwamandla okuvama okuphakathi, futhi ukusetshenziswa kwayo okunembile kubalulekile ekusebenzeni kwesikhungo. Kuyinto evamile ukuthi isithando somlilo esincibilikayo silimaza ama-thyristors amaningana ngonyaka. Uma i-thyristor ishiswa njalo, isithando somlilo sikagesi sizoyeka ukukhiqiza, okuzothinta ukukhiqizwa, futhi kubangele ukuqapha. Ukusebenza kwamanje kwe-thyristor kusuka kumakhulu amaningana ama-ampere kuya ezinkulungwaneni zama-ampere, futhi i-voltage ngokuvamile i-volts eyodwa noma ezimbili. Ukuvikelwa okuhle kwebhodi lokulawula eliyinhloko kanye nezimo ezinhle zokupholisa amanzi kuyadingeka.

Izici zokulayisha ngokweqile ze-thyristor: Ukulimala kwe-thyristor kubizwa ngokuthi i-breakdown. Ngaphansi kwezimo ezijwayelekile zokupholisa amanzi, umthamo wamanje wokugcwala ungafinyelela ngaphezu kuka-110%; akukho umthamo we-voltage overload, okungukuthi, i-silicon ilimele nakanjani ngaphansi kwezimo zokugcwala ngokweqile. Ngokucabangela i-voltage yokuqhuma, abakhiqizi bavame ukukhetha izingxenye ze-silicon ngokusekelwe izikhathi ezingu-3-4 ze-voltage yokusebenza lapho izikhungo zokukhiqiza.

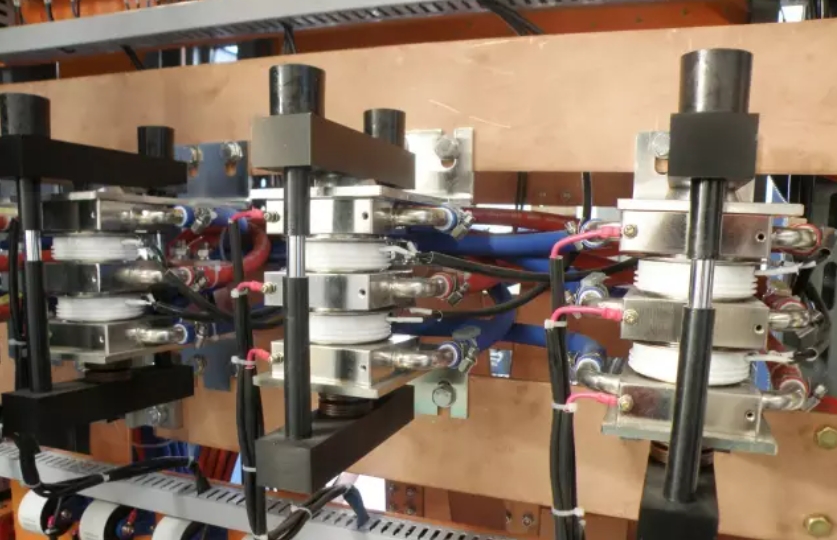

Ukucindezela okunembile kokufaka kwe-SCR: 150-200KG/cm2. Lapho isikhungo siphuma embonini, ngokuvamile sifakwa umshini wokunyathelisa osebenza ngogesi. Amandla aphezulu we-wrench evamile awakwazi ukufinyelela leli nani, ngakho-ke asikho isidingo sokukhathazeka ngokuthi i-silicon ichotshozwa lapho ukucindezela kufakwa ngesandla; uma ukucindezela kukhululekile, kuzoshisa i-silicon ngenxa yokushisa okuphansi kokushisa.

Isakhiwo se-radiator ye-SCR: umgodi opholile ngamanzi + ukusekelwa kwezinsika eziningi zethusi. Uma amanzi ajikelezayo enzima kakhulu, azokhula emgodini wamanzi futhi abangele ukuchithwa kokushisa okubi; uma amaqabunga nezinye izibi zingena emgodini wamanzi, kuzobangela nokugeleza kwamanzi okungekuhle.