- 05

- Sep

Indlela yokukhetha uhlelo lokupholisa amanzi avaliwe lwesithando somlilo sensimbi encibilikisiwe

Indlela yokukhetha uhlelo lokupholisa amanzi avaliwe lwesithando somlilo sensimbi encibilikisiwe

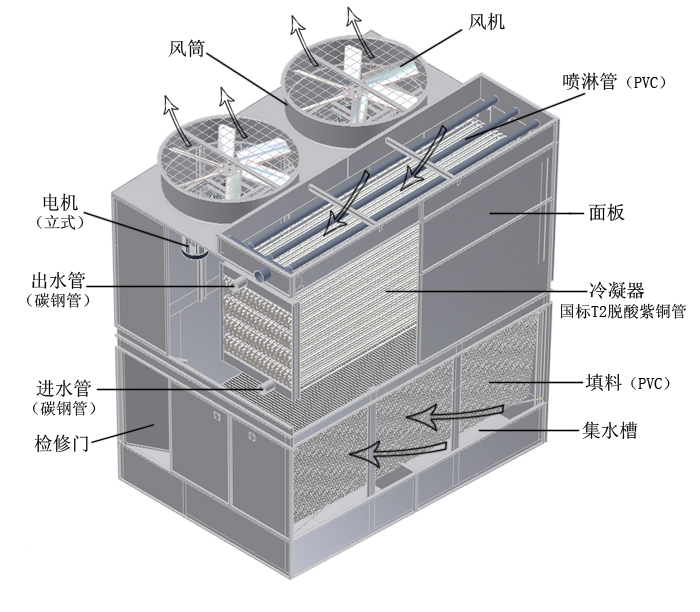

Isistimu yokupholisa ngamanzi omoya isesimweni sombhoshongo wokupholisa ovaliwe. Isistimu yokupholisa evaliwe ayidingi ukumba ichibi, futhi isayithi lidinga kuphela ukuxhuma isixhumi esibonakalayo nezinto zokusebenza okumele zipholile, ngaphandle kokwengeza ezinye izinto ezisizayo. Isethi yonke yamanzi esistimu yokujikeleza ingamanzi athambile, izinga lamanzi lihle, isikali asikalwanga, i-loop evaliwe yenza ukulahlekelwa kwamanzi kube kuncane kakhulu, futhi izindleko zokusetshenziswa nokugcinwa kwemishini zingancishiswa kakhulu. Njengoba ingxenye kagesi kanye nengxenye yesithando somlilo kunezidingo ezihlukene ekushiseni kwamanzi, okungukuthi, izinga lokushisa lokushisa lengxenye yesithando somlilo liphakathi kuka-35-55 ° C (i-angle yokulondoloza amandla isindisa amandla), kanye nogesi. ingxenye idinga ukwehlisa izinga lokushisa lamanzi. Izinga eliphansi, kunconywa ukusebenzisa amasethi amabili emibhoshongo yokupholisa evaliwe ukuze uhlukanise ingxenye kagesi kanye nengxenye yesithando somlilo.

Izici ze-cooler ye-fluid:

Umbhoshongo wokupholisa ovaliwe ongu-1 FL unesitayela futhi muhle, unokwakheka kwangaphakathi okuhlangene kanye nesakhiwo esinengqondo;

2 Ipuleti legobolondo langaphandle lenziwe ngeshidi elingu-2mm eliwugqinsi lokucwilisa elishisayo (ozikhethela ipuleti lensimbi engagqwali), elishiselwe, ligoqwe futhi libhotshwe ithuluzi lomshini we-CNC futhi lihlanganiswe ngaphandle kwe-weld seam. Usayizi unembile futhi uyisicaba;

I-cooler engu-3 (ingxenye eyinhloko) yenziwe ngeshubhu yethusi elisezingeni lomhlaba elingu-T 2, elinamajoyinti ambalwa e-solder futhi lishiselwe nge-electrode esiliva;

I-4 PVC high-efficiency dehydrator ingenza izinga lokukhukhuleka kwamanzi libe ngaphansi kuka-0.001%, okwenza kube nokwenzeka ukubeka okokusebenza ezindaweni ezingezwani namanzi;

I-grille yesitayela se-PVC ephezulu ye-5, ukumelana nomoya omncane, ukunciphisa ukusetshenziswa kwamandla kwe-fan futhi ngeke kube khona ukufafaza kwamanzi okufafaza, ilanga ngeke lifinyelele ngaphakathi kosinki, livimbele ngempumelelo ukukhula kolwelwe;

6 Isiteshi sokumpompa sakhiwe ipompo enkulu yamanzi kanye nephampu yamanzi eyisipele. Uma iphampu yamanzi eyinhloko ihluleka, iphampu yamanzi elindile ingaqalwa ngokushesha, okwenza ukuhlinzekwa kwamanzi okuqhubekayo kwenzeke. Uma kwenzeka ukuphela kukagesi, iphampu yesimo esiphuthumayo yenjini kaphethiloli ingakhethwa ukuze umsebenzisi aqedele ukupholisa okuqhubekayo kwekhoyili yokungeniswa;

Uhlelo lokupholisa amanzi avaliwe

7 fan izindwani kukhona ingxubevange aluminium, motor igobolondo aluminium anti-motor ezintathu, brand ezifuywayo odumile;

8. ithangi lamanzi elijikelezayo lenziwe ngepuleti lensimbi engagqwali elingu-304 futhi line-alamu yezinga loketshezi elingenisiwe;

9. Umbhoshongo wokupholisa ovaliwe unikezwa kusibonisi sengcindezi ye-inlet, ukunikezwa kwamandla esithandweni kuphinde kuhlinzekwe nge-inlet yokucindezela kusibonisi (indawo yokufaka), ingcindezi ehlukile efundwa ukwehla kokucindezela kwamanzi, ukuze kuzuzwe ngempumelelo. ukupholisa, ukuze kuqinisekiswe ukuthi idivayisi Ububanzi bokugeleza kwamanzi aphephile;

10. Umbhoshongo wokupholisa ovaliwe unombukiso wokushisa wamanzi nomsebenzi we-alamu endaweni yokukhipha amanzi, futhi ungakwazi ukulawula izinga lokushisa lamanzi okungenisa nokukhipha ngokusebenzisa isilawuli sezinga lokushisa ledijithali ukulawula ukuvulwa nokuvalwa kwesistimu yesifutho. Umbhoshongo wokupholisa ovaliwe upholiswa ngokuqhubekayo nangokuphephile nangempumelelo amandla aphakathi kwamafrikhwensi amaphakathi kanye nomzimba wesithando somlilo ngaphakathi kwebanga lokushisa elinqunywe kusengaphambili.

Umzila wamanzi ojikelezayo opholisayo kukhabhinethi yokuphakelwa kwamandla kagesi wemvamisa emaphakathi kanye nebhange le-capacitor yesinxephezelo lixhunywe ngamapayipi ensimbi engagqwali. Ukuxhumana kuthembekile futhi uphawu lusobala. Ingakwazi ukumelana nezikhathi ezingu-1.5 zokucindezela kwangaphakathi kokuklama kwamanzi ngaphandle kokuvuza.