- 09

- Mar

Ukubaluleka kokugcinwa kwansuku zonke kwesithando somlilo sokuncibilika

Ukubaluleka kokugcinwa kwansuku zonke kwesithando somlilo sokuncibilika

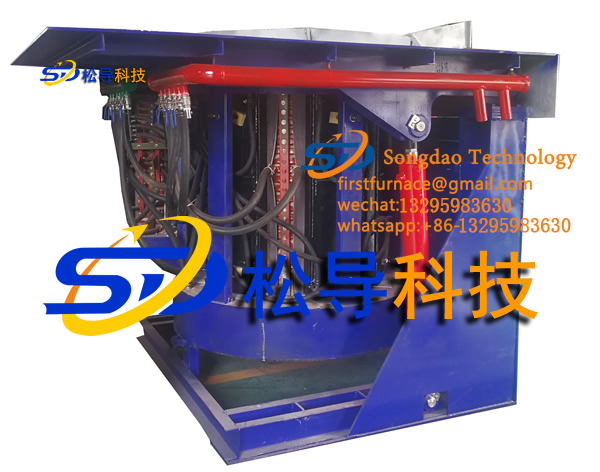

In the daily production of ukuchithwa kwesithando somlilo, in addition to operating the induction melting furnace correctly and reasonably, the operating staff must also carefully and carefully do the daily maintenance of the induction melting furnace. During the operation of the induction melting furnace, due to system failure, component failure, mechanical loss or chemical corrosion, etc., it will inevitably cause abnormal operation. In order to avoid rapid damage and prevent the expansion of faults, maintenance work must be done during daily use.

Okuqukethwe okuyinhloko kokugcinwa kwansuku zonke kwesithando somlilo sokuncibilika kwe-induction ukuhlanza, ukukhipha uthuli, ukuvikela ukugqwala nokulungiswa. Ifekthri kufanele inikeze imibhalo yezobuchwepheshe eyanele (njengezinqubo zokusebenza, izinto zokunakekela kanye namashadi emiyalo, njll.) opharetha bepunch yokuncibilika kwesithando somlilo. Lapho isithando somlilo se-induction esincibilika esikhiqizwa yi-Yuantuo Electromechanical silethwa kukhasimende

Ngaleso sikhathi, sizochazela amakhasimende ngezindaba okufanele zinakekelwe ekugcinweni kwesithando somlilo sokuncibilika, okuthuthukisa kakhulu impilo yesevisi yesithando somlilo sokuncibilika.

Ukuze yenze umsebenzi omuhle wokulungisa, ifektri kufanele yenze izinhlelo ezihlukahlukene zokulungisa, ihlale igcina isithando somlilo esincibilikisa intuthuko, futhi yenze uhlelo olufanele lokunakekela ukuze sigcinwe sisesimweni esivamile ngokuvumelana neziqondiso zokunakekela ezinikezwa umenzi wesithando somlilo esincibilika. Kodwa-ke, kungakhathaliseki ukuthi hlobo luni lwesistimu yokulungisa eyakhiwe, ububanzi nokuqukethwe komsebenzi ohlukahlukene wokulungisa kufanele kucaciswe kahle, futhi ikakhulukazi, umngcele phakathi “kokugcina” kanye “nokulungisa” kufanele uhlukaniswe. Uma kungenjalo, kulula ukubangela ukunqanyulwa noma ukuphindwaphindwa kokugcinwa nokulungiswa, noma ngenxa yohlu olubanzi nokuqukethwe okuningi kakhulu, umthwalo wangempela womsebenzi ongowezinga lokulungisa kunzima ukunamathela kuwo isikhathi eside, futhi kulula ukuwenza. kube okusemthethweni, futhi kuzoletha ukuphathwa kwesabelo kanye nokuphathwa okuhleliwe. Izingqinamba eziningi.

Ngokuvamile, umthwalo wemfanelo oyinhloko wokulungisa uwukwenza indawo yokusebenza enhle yesithando somlilo esincibilikayo. Izinto eziyinhloko zomsebenzi wesondlo akufanele zibe ziningi kakhulu, zilula futhi zilula ukwenza, isihluthulelo siwukukwazi ukuphikelela isikhathi eside. Izingxenye eziningi zokulungisa zingaphandle kwesithando somlilo esincibilikisa induction, futhi asikho isidingo sokuhlakazeka, futhi singaqedwa ngaphandle kokuthinta ukusebenza, futhi asikho isidingo sokuhlela ngamabomu isikhathi sokugcina. Izinto ezisetshenziselwa umsebenzi wokulungisa ngamunye aziningi kakhulu, zilula futhi zilula.