- 12

- Oct

Indlela yokukhetha yesithando somlilo esincibilikisa igobolondo le-aluminium igobolondo lensimbi

Indlela yokukhetha igobolondo lensimbi ye-aluminium ukuchithwa kwesithando somlilo

Umzimba wesithando somlilo we-induction uhlanganisa umzimba wesithando somlilo kagesi, ikhebula elipholile ngamanzi, usimende ophikisayo, uhlelo lwesithando somlilo esitshekisa ugesi, njll.

![14-1 [1]](https://songdaokeji.cn/wp-content/uploads/2022/10/202210120037026.jpeg)

Umdwebo ohleliwe wokubekwa kwamakhabethe kagesi wefrikhwensi ephakathi, amakhabethe e-capacitor kanye neziko elincibilikayo

1. Isithando Somlilo

Umzimba wesithando somlilo wakhiwe ngekhoyili yokungeniswa, igobolondo le-aluminium alloy furnace, idivayisi yokutshekisa isithando somlilo kagesi, njll.

6.1.1 Ikhoyili yokungeniswa

Ikhoyili yokungeniswa yenziwe ngeshubhu yethusi elingunxande elingu-99.99% T2. I-insulation surface yekhoyili yokungeniswa ifafazwa ngongqimba lwe-epoxy insulating resin enamandla amakhulu ngenqubo yokufafaza i-electrostatic, bese i-mica tape isongwe bese isongwe ngendwangu emhlophe yokwelashwa kokucwiliswa, isendlalelo sokufakwa kwe-insulation I-voltage yokumelana inkulu kuno-5000V. .

Ikhoyili ye-induction ilungiswa ngochungechunge lwamabhawodi kanye nezindawo zokuvikela ezokuvikela ezishiselwe esiyingini sayo sangaphandle. Ngemva kokuba ikhoyili isilungisiwe, iphutha lokujika kwayo alikho ngaphezu kuka-1.5mm.

2. Imingcele yekhoyili yokungeniswa nokushaja

Imingcele yekhoyili yokungeniswa kanye nokushaja kulungiselelwe futhi kuklanywe ngesofthiwe yekhompyutha ekhethekile. Ingaqinisekisa ukusebenza kahle kakhulu kokuxhumana kwe-electromagnetic ngaphansi komthamo ofanayo. Uma kucatshangelwa ukuthi isithando somlilo sikagesi sidinga ukufakwa ngokweqile, umthamo olinganiselwe wenziwe mkhulu kancane kunomthamo wegama edizayini. Kuphela ngale ndlela kungaqinisekiswa ukuthi izinga le-liquid lokukhokhiswa alidluli indiza ephezulu yendandatho epholile ngamanzi lapho isithando somlilo sikagesi sisenani eliphezulu lokushaja. Ngenxa yokuthi ingxenye yesithando somlilo ngaphezu kwendandatho epholile ngamanzi ayipholile, uma le ngxenye ihlangene nenkokhelo isikhathi eside, kuzokhiqizwa izinga lokushisa eliphakeme, elizokwenza ukuthi uhlaka lwesithando luqhekeke emanzini angaphezulu. -ndandatho epholile.

3. Ikhebula elipholile ngamanzi

Ijoyinti lekhebula elipholise amanzi liboshwe ngocingo oluboshwe ngethusi kusetshenziswa inqubo yokubumba ebandayo. Ngale ndlela, uxhumano luqinile, ukumelana nokuxhumana kuncane, futhi ucingo oluboshwe ngethusi alonakali. Ijoyinti elilodwa kanye nentambo yethusi ingamelana namandla aqinile angaphezu kuka-8t. Ishubhu elingaphandle lekhebula elipholiswe ngamanzi lithatha ishubhu lerabha eliyisipesheli elikwazi ukumelana nomlilo. Lolu hlobo lwepayipi akulula ukulushisa futhi lunamandla amahle. Iyakwazi ukumelana nomfutho wamanzi ongu-0.5Mpa ngaphandle kokuvuza noma ukugqabuka.

Intambo epholile yamanzi

4. Udaka lwe-Refractory

I-coil Cement yenziwe nge-refractory Cement ekhethekile yamakhoyili we-US Allied Mines smelting furnace, enezici zamandla amahle, ukumelana nokushisa okuphezulu, kanye nokushisa okuhle.

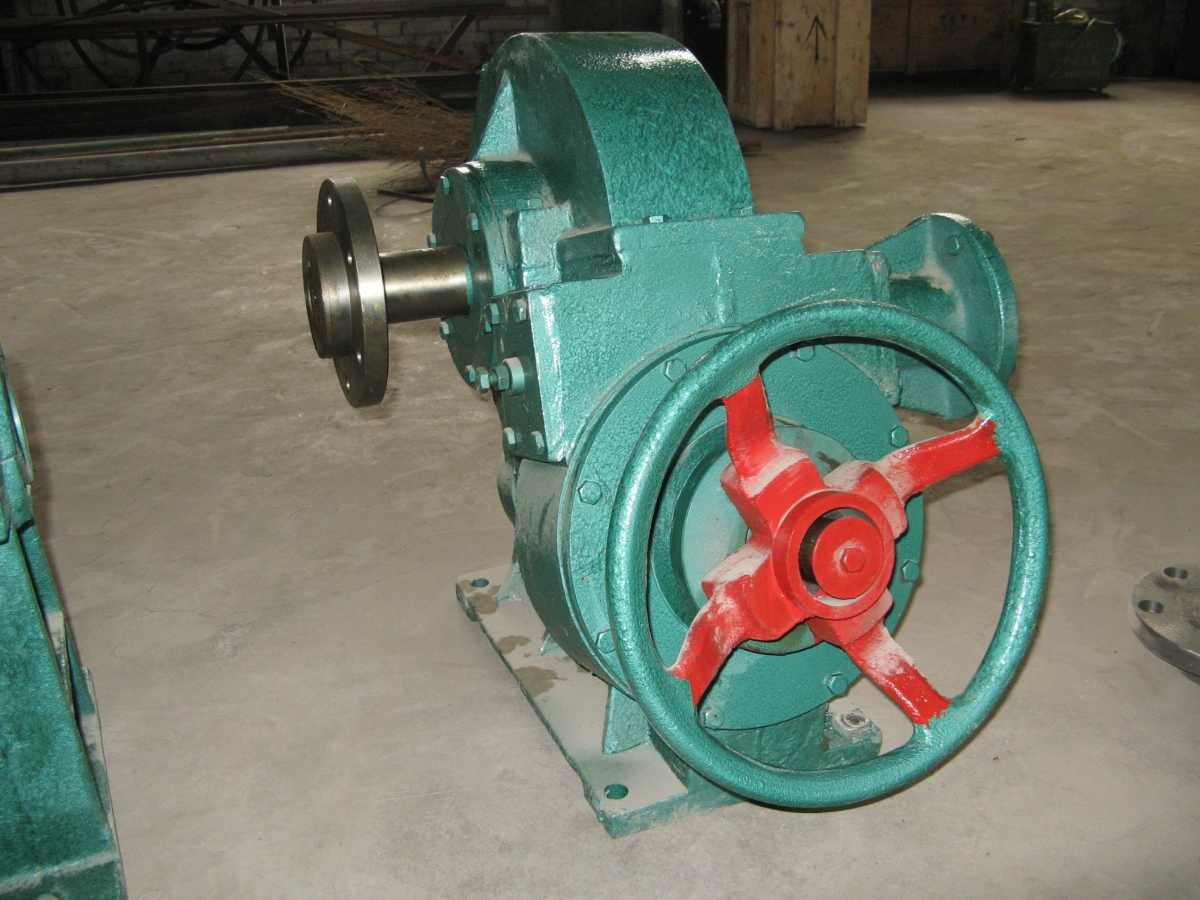

5. Isinciphisi sesithando somlilo esitshekisayo samukela isinciphisi esikhethekile sesithando somlilo esikhiqizwa abakhiqizi basekhaya abaziwayo, ngesivinini sokutshekisa okufanayo kanye nekhwalithi ethembekile. Ukutshekiswa kwesithando somlilo wesithando somlilo esiphakathi nendawo kuqhutshwa ngokuqondile ibhokisi lokunciphisa isithando somlilo esitshekisayo. I-tilting furnace reducer iyigiya lezikelemu elinezigaba ezimbili elinokusebenza okuhle kokuzikhiya nokuzungeza okuzinzile nokuthembekile. Esimeni lapho amandla engasebenzi ngendlela ephuthumayo, isithando somlilo singatshekiswa ngesandla ukuze kugwenywe ingozi yokushisa ikhoyili ngenxa yokushisa okweqile esithandweni.

Nciphisa