- 12

- Oct

Selection method of aluminum shell steel shell induction melting furnace

Selection method of aluminum shell steel shell induction melting furnace

Induction furnace body includes electric furnace body, water-cooled cable, refractory cement, electric tilting furnace system, etc.

![14-1[1]](https://songdaokeji.cn/wp-content/uploads/2022/10/202210120037026.jpeg)

Schematic diagram of placement of intermediate frequency power supply cabinets, capacitor cabinets and melting furnaces

1. Furnace

The furnace body is composed of induction coil, aluminum alloy furnace shell, electric furnace tilting device, etc.

6.1.1 Induction coil

The induction coil is made of 99.99% T2 rectangular copper tube. The surface insulation of the induction coil is sprayed with a layer of high-strength epoxy insulating resin by electrostatic spraying process, and the mica tape is wrapped and then wrapped with white cloth tape for immersion treatment, insulation layer The withstand voltage is greater than 5000V.

The induction coil is fixed by a series of bolts and insulating stays welded on its outer circumference. After the coil is fixed, the error of its turn pitch is not more than 1.5mm.

2. Parameters of induction coil and charge

The parameters of the induction coil and the charge are optimized and designed with special computer software. It can ensure the best electromagnetic coupling efficiency under the same capacity. Taking into account that the electric furnace needs to be over-installed, the rated capacity is artificially slightly larger than the nominal capacity in the design. Only in this way can it be ensured that the liquid level of the charge does not exceed the upper plane of the water-cooled ring when the electric furnace is at the maximum charging amount. Because the part of the furnace lining above the water-cooled ring is not cooled, if this part is in contact with the charge for a long time, a higher temperature will be generated, which will cause the furnace lining to crack at the upper water-cooled ring.

3. Water-cooled cable

The joint of the water-cooled cable is crimped with the copper stranded wire using a cold forming process. In this way, the connection is firm, the contact resistance is small, and the copper stranded wire is not damaged. The single joint and the copper wire can withstand a tensile force of more than 8t. The outer tube of the water-cooled cable adopts a special flame-retardant rubber tube. This kind of hose is not easy to burn and has good strength. It can withstand 0.5Mpa water pressure without leakage or rupture.

Water-cooled cable

4. Refractory mortar

The coil cement is made of special refractory cement for the coils of the U.S. Allied Mines smelting furnace, which has the characteristics of good strength, high temperature resistance, and good insulation.

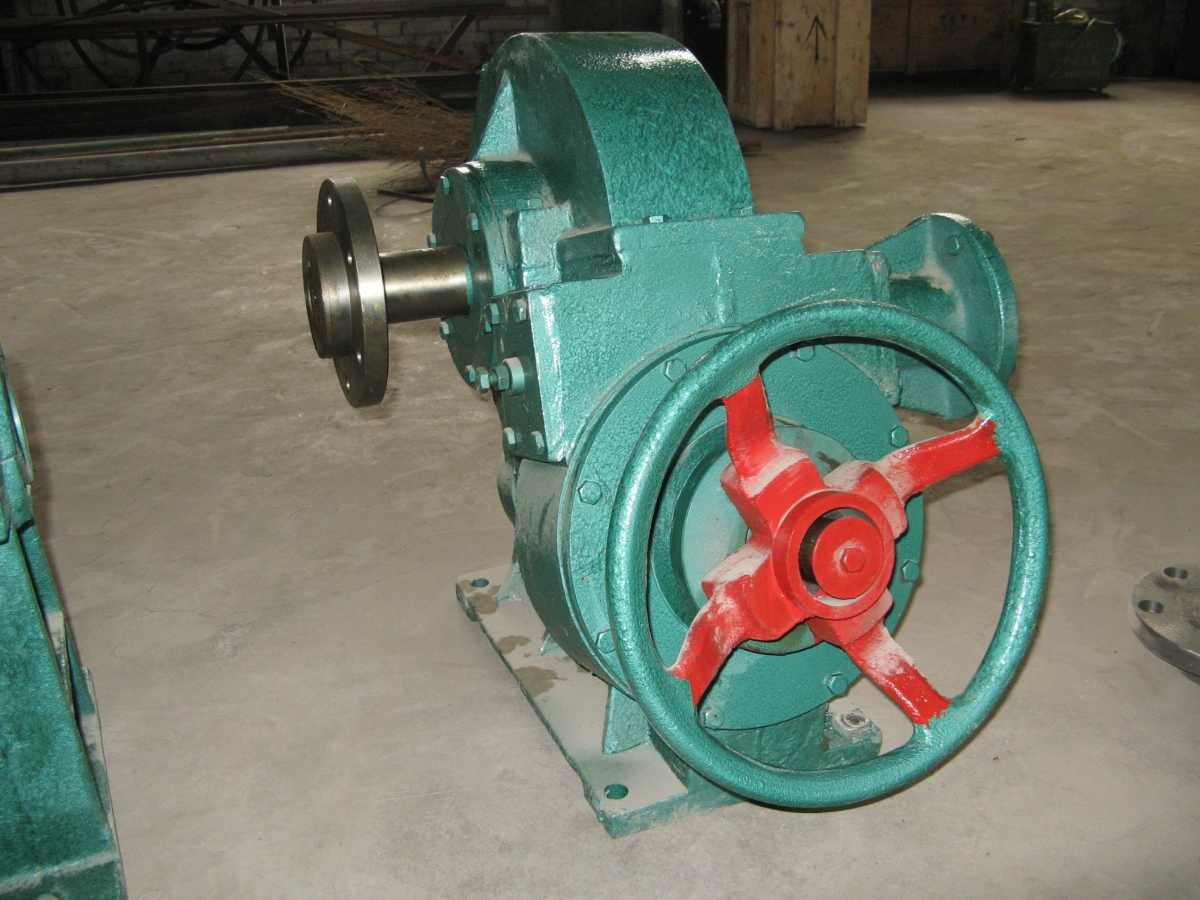

5. The reducer for tilting furnace adopts the special reducer for induction furnace produced by well-known domestic manufacturers, with uniform tilting speed and reliable quality. The tilting of the furnace body of the intermediate frequency electric furnace is directly driven by the tilting furnace reduction box. The tilting furnace reducer is a two-stage worm gear with good self-locking performance and stable and reliable rotation. In case of emergency power failure, the furnace can be manually tilted to avoid the danger of burning the coil due to excessive temperature in the furnace.

Reducer