- 18

- Sep

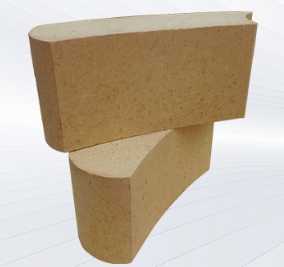

Curved refractory brick

Curved refractory brick

High quality and excellent price, good service

Product advantages: good thermal shock resistance, strong corrosion resistance, high compressive strength.

product description

Arc-shaped refractory bricks are also called arc bricks. High-alumina arc bricks are a kind of special-shaped bricks. The arc of the arc brick is semi-circular and the other end is a groove. , Can also be built into a circle, this kind of brick is used in the ladle. The arc brick is mainly used as the inner lining of the steel bucket. It used to be mainly clay. Now it is gradually replaced by high alumina bricks. High alumina bricks are characterized by good thermal shock resistance, strong corrosion resistance and high compressive strength.

High-aluminum arc refractory bricks contain aluminum silicate with Al2O3 above 48% to 75%. The higher the aluminum content, the better the quality of high-aluminum arc bricks. It is a weakly acidic refractory material, which is made of natural or artificial high-alumina materials (sillimanite, diaspore, high alumina, etc.). Compared with clay bricks, its refractoriness (1750~1790℃) and load softening temperature (1420~1500℃) are higher, and its slag resistance and compressive strength are also higher.

Physical and chemical indicators

| Rank/Index | High alumina brick | Secondary high alumina brick | Three-level high alumina brick | Super high alumina brick |

| LZ-75 | LZ-65 | LZ-55 | LZ-80 | |

| AL203 ≧ | 75 | 65 | 55 | 80 |

| Fe203% < | 2.5 | 2.5 | 2.6 | 2.0 |

| Bulk density g/cm2 | 2.5 | 2.4 | 2.2 | 2.7 |

| Compressive strength at room temperature MPa> | 70 | 60 | 50 | 80 |

| Load softening temperature °C | 1520 | 1480 | 1420 | 1530 |

| Refractoriness °C> | 1790 | 1770 | 1770 | 1790 |

| Apparent porosity% < | 24 | 24 | 26 | 22 |

| Heating permanent line change rate% | -0.3 | -0.4 | -0.4 | -0.2 |