- 23

- Sep

Pay attention to the following points when choosing a sliding nozzle for ladle

Pay attention to the following points when choosing a sliding nozzle for ladle

The selection of the sliding nozzle mechanism should take into account the safety, stability, reliability, convenience and cost based on the size of the ladle, and the following aspects should also be paid attention to when choosing:

1. Skateboard positioning method

The positioning characteristics of the skateboard: the sliding surface should be smooth, flatness ≤0.05mm; high mechanical strength; strong corrosion resistance to molten steel and slag; not easy to adhere to molten steel.

2. Water inlet positioning method

There is no complete positioning method for the upper nozzle. It is adjusted according to the taper of the upper nozzle and the nozzle block and the amount of fire mud. It is easy to be unable to accurately locate the position.

3. Guard plate

The protective plate function of the sliding mechanism is the heat radiation and splashing of the molten steel in the tundish to the mechanism. If the guard plate cannot move with the sliding parts at the same time, it is easy to cause deformation of the guard plate and steel gushing. Need to pay attention to avoidance.

4. Spring way

The spring of the sliding mechanism has the characteristics of anti-corrosion, not easy to rust, environmental protection and durability.

5. Convenient operation

Attention should be paid to the on-site operation space and the replacement of upper and lower slides and the operation of the water inlet.

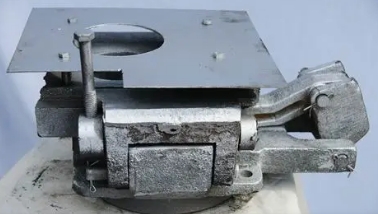

Sliding nozzle

6. Accessories

The main components of the sliding mechanism are wheels, axles, sliding strips, guard plates, springs, etc. It is best to synchronize with the body of the mechanism for the best life, and it is best to choose imported high-grade stack springs for the springs.

7. Maintainability

The whole mechanism adopts a precision-cast frame. In the normal maintenance process, since the slider and the frame are integrated, one is separated from the base, only the frame and the sliding parts need to be hoisted away and the wiring can be changed quickly during maintenance.

8. Refractory

The sliding mechanism refractory material selection is based on the principle of not increasing the refractory material mold and changing the existing operation mode as little as possible.

9. Calculation of Pouring Steel Diameter of Ladle Slide Plate

It is necessary to consider the size of the aperture of the slide plate, and also consider the fastest pouring speed of the ladle, the lowest pouring tonnage, and the drawing speed, etc., and there is also a suitable margin.