- 24

- Sep

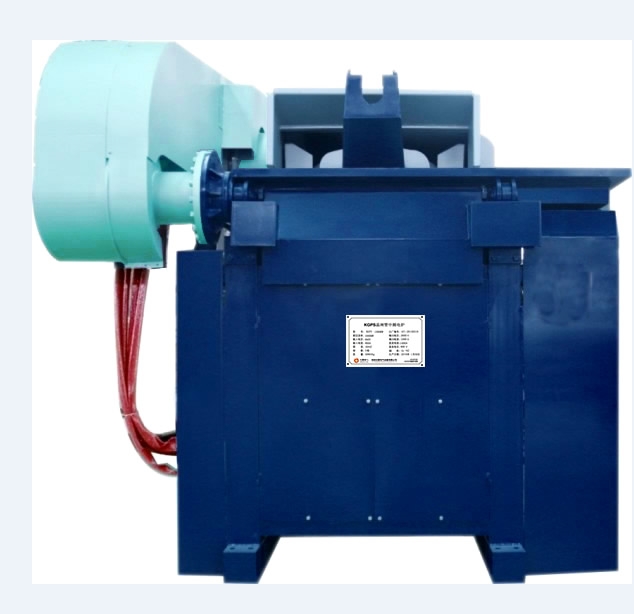

3 T brass and copper induction melting furnace

3 T brass and copper induction melting furnace

A . 3T intermediate frequency melting furnace project list:

| Serial number | name | Require | unit | quantity | Remark |

| 1 | 3 T induction melting furnace | Melting brass, copper material | set | 1 | One machine and two furnaces |

B. 3 T induction melting furnace process flow

The 3 T induction melting furnace complete set of equipment is used for the melting of brass and red copper materials and combined with the casting process to complete the rough processing and finishing of copper materials. The operations staff copper raw materials and scrap into the furnace → material by heating to a rated frequency heating equipment melting temperature . 1 . 7 00 → deg.] C by playing the slag, in addition to a series of gas treatment processes such as the molten liquid metal after preliminary purification → hydraulically furnace The metal liquid in the body is poured into the transfer ladle → the casting process is carried out through the ladle.

C. 3 T induction melting furnace composition requirements:

The intermediate frequency power supply is an AC – DC – AC static frequency conversion device that converts 50Hz three-phase power frequency electrical energy into single-phase electrical energy. Using the principle of electromagnetic induction, the heated material is placed in an alternating magnetic field to generate eddy current loss and generate heat, which meets the requirements of melting . The heating method has the advantages of fast heating, less burnout, low labor intensity, can ensure product quality and easy to organize automatic production lines.

| Device model | Rated power rate (KW) | Intermediate frequency (KHZ) | Rated input

Current ( A ) |

Intermediate frequency voltage (V) | Furnace voltage (V) |

| CF-1600KW | 1600 | 0.5 | 3200 | 750 | 1200 |

| Transformer one

Secondary voltage ( KV ) |

Transformer 2

Secondary voltage ( V ) |

DC voltage

( V ) |

DC current ( A ) | Startup success rate | |

| 10 | 750 | 1120 | 3370 | 100% | |

| Rectified pulse number | Transformer capacity (KVA) | Cooling water flow

Quantity (T/H) |

Working noise db | ||

| 12 | 3600 | 25 | ≤75 |

Basic parameters

D . IF intermediate frequency furnace to melt a major component of the furnace equipment, the furnace shell, refractories, hydraulic systems, cooling water, cables and other components.

Basic parameters

| Model of melting furnace | Rated Capacity

( T) |

Maximum capacity

(T) |

Furnace voltage

(V) |

Melting rate

(T/H) |

Melting time (MIN/ furnace ) |

| CF – 1600KW | 3 | 3.5 | 1200 | 3 | 90 |

| Working furnace temperature ( ℃ ) | Maximum furnace temperature ( ℃ ) | Lining thickness ( mm ) | Induction coil inner diameter ( mm ) | Induction coil height ( mm) | |

| 1 7 00 | 175 5 | 150 | |||

| Power consumption (KWH/T) | Cooling water flow (T/H) | Hydraulics system | |||

| 4 50 | 5 0 | 4 50L 11Mpa |