- 26

- Sep

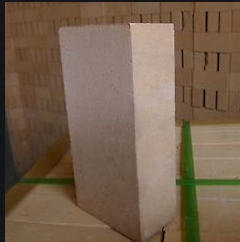

Silica Brick

Silica Brick

Silica brick refers to products with SiO2 content above 90%. Silica brick is made of silica with SiO2 content not less than 96% as raw material.

It is prepared by mixing, forming, drying and sintering the mineralizer and binding agent. The higher the SiO2 content in the silica raw material, the higher the refractoriness of the product. There are many varieties of silica bricks, which are divided into: silica bricks for coke ovens, silica bricks for hot blast stoves, silica bricks for electric furnaces, and silica bricks for glass kilns. According to the transformation, it is divided into: standard bricks, general bricks, special-shaped bricks and special-shaped bricks.

Characteristics of silica bricks:

Silica brick is an acidic refractory material, which has strong resistance to acid slag or acid solution. The higher softening temperature under load is an excellent characteristic of silica brick, generally 1640-1680℃.