- 04

- Oct

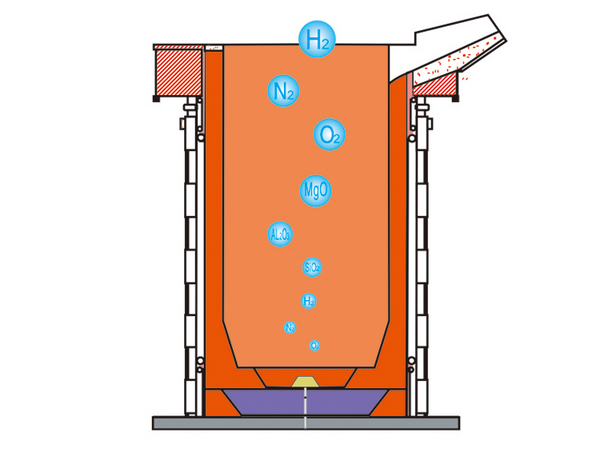

Dry vibrating material for intermediate frequency furnace

Dry ramming material for intermediate frequency furnace

(Intermediate frequency furnace lining material)

Provide refractory materials for coreless induction furnaces and vacuum furnace sleeves used in steel casting plants. The hot surface furnace lining still has corrosion resistance and mechanical properties under long-term exposure to the high temperature of molten steel. Continuously optimized product formula and construction technology. On the premise of ensuring the safety of personnel and equipment, the service life of the furnace lining is prolonged. The product is suitable for the melting and heat preservation of carbon steel, stainless steel, alloy steel and other steel grades. The engineers of Tong Kiln are willing to serve you and can develop products for you according to your new needs.

Mid-range dry vibrating material

It is a cost-effective dry vibrating material, which is composed of bauxite clinker, corundum, spinel, magnesia, sintering agent, etc. It is suitable for the melting of carbon steel, alloy steel, stainless steel and high manganese steel, with long life and high cost performance.

This material has been used by many foundry companies, and the results are very good, realizing low cost and long life.

Mid-range dry vibration cooking index:

| Material | Bauxite-Spinel | Typical value |

| No | DRY-RAM85A | |

| AL2O3,% | ≥72 | 73.25 |

| MgO,% | ≥18 | 18.96 |

| Body density, g/cm3 | ≥2.8 | 2.83 |

| Normal use temperature ℃ | 1600~1650 | 1600~1650 |

| The upper limit of operating temperature (short time)℃, | 1700 | 1700 |

| Granularity, mm | 5 | 5 |