- 05

- Oct

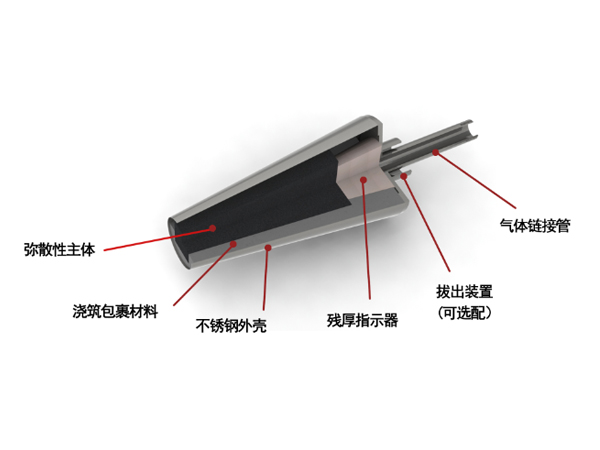

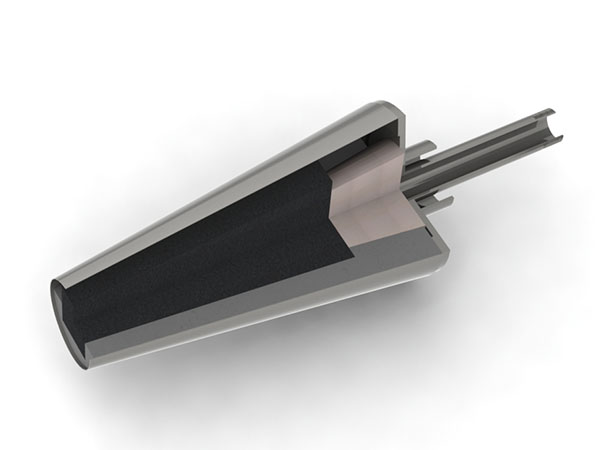

Mixed dispersion type breathable brick core

Mixed dispersion type breathable brick core

Product name: Mixed and diffuse air-permeable brick core

As people have higher and higher requirements for the quality of steel, it is necessary to improve steelmaking technology and steelmaking process. Out-of-furnace refining technology is an important part of the refining process in the steelmaking process, which can adjust the composition of steel and the temperature of molten steel. The breathable brick is a key functional element for the smooth implementation of this process, and it plays a vital role in the reliability and completeness of the refining outside the furnace. Due to the large-scale development of ladle, the melting temperature and melting time have been increased successively, making the environment that refractory materials are subjected to during use becomes more and more demanding. Therefore, it is necessary to make progress and improve the performance of breathable bricks to meet contemporary steelmaking Process and steelmaking technology requirements for breathable bricks.

Usability:

1, slag resistance

In order to improve the material’s slag resistance and resistance to molten steel penetration, corundum spinel ventilated bricks usually add Cr2O3 or add part of chromium corundum. Cr2O3 and a-Al2O3 have the same crystal structure. Cr2O3 not only improves the slag resistance of the material, but also increases the wetting angle between the material and the molten steel, and significantly improves the blockage of the pores of the breathable brick due to the penetration of molten steel.

Using Cr2O3 fine powder and Al2O3 at high temperature to form the aluminum-chromium solid solution and the existing chromium-containing glass phase, the liquid phase formed when it comes into contact with the slag in the molten steel smelting process has a fixed viscosity, thereby preventing the slag in the molten steel from affecting the breathable brick Corrosion; At the same time, it can absorb iron oxide and magnesium oxide in the slag, and form dense spinel in the working layer of the ventilating brick, which improves the slag resistance of the ventilating brick.

But adding Cr2O3 to the material, after high-temperature firing or use, Cr3+ is oxidized to Cr6+, which is toxic and pollutes the environment. Therefore, for energy conservation and environmental protection, the use of Cr2O3 should be avoided as much as possible, and by replacing raw materials, the high temperature performance without adding Cr2O3 can reach the level of adding Cr2O3.

2, thermal shock resistance

The main damage method of breathable bricks is thermal shock damage. With the continuous increase of the tapping temperature, there is a large temperature difference between working and intermittent work on the working surface of the ventilating brick, which requires the material to have high thermal shock resistance. The spinel phase is introduced into the castable, and the thermal shock resistance of the air-permeable brick will be improved.

Oxide or non-oxide added to the air-permeable brick forms a solid solution phase with the aggregate at high temperature, which increases the high-temperature strength of the brick, improves the permeability of the brick, and resists the erosion of the air-permeable brick by the molten slag in the ladle. After the high temperature heat treatment of the air-permeable brick, its performance is improved to meet its use requirements.