- 05

- Oct

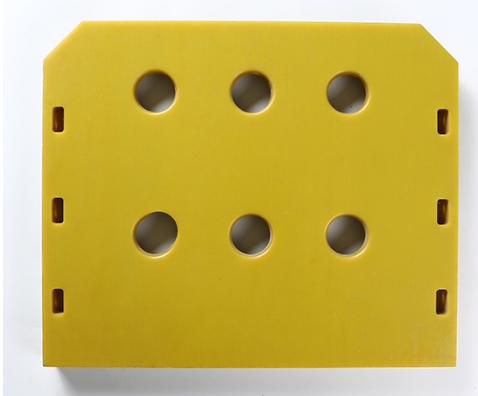

Production process of epoxy glass fiber board processing

Production process of epoxy glass fiber board processing

Epoxy glass fiber board, epoxy phenolic laminated glass cloth board, epoxy resin generally refers to organic polymer compounds containing two or more epoxy groups in the molecule, except for a few, their relative molecular masses are not high.

The main characteristics of epoxy glass fiber board processing: because of its 7 million ultra-high molecular weight, it has extremely high impact strength, high impact kinetic energy absorption rate, strong modulus, and outstanding resistance to abrasion and sliding under high stress. Characteristics, dimensional stability is still maintained when warm. Anti-ultra-low temperature -265℃. Even at low temperatures and even at low temperatures, it still maintains very excellent tensile strength and notch impact strength, acid and pigment resistance.

Epoxy glass fiber board processing

According to the production of epoxy glass fiber board, it is possible to increase the high-density polyethylene tin board, and in the process of relative low density, it can increase the stable melting temperature and the relative temperature of the melting point.

According to the epoxy glass fiber board processing procedure, it can increase the processing smoothness in a wide range of applications, promote the main characteristics, and stabilize the shrinkage in the process of melting with the chemical and the substance, which can improve the The process at room temperature and the connection of the solution will not cause melting.