- 11

- Oct

Refractories for large cement rotary kilns

Refractories for large cement rotary kilns

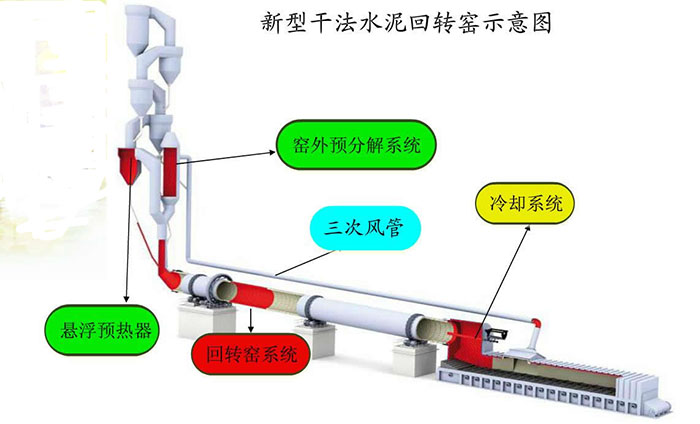

The new dry-process cement rotary kiln is divided into a suspension preheater, a precalcining system outside the kiln, a rotary kiln system, a tertiary air duct, and a cooling system.

The cement rotary kiln requires refractories to have the following characteristics:

①Corrosion resistance.

② Thermal shock resistance stability.

③Abrasion resistance.

Based on the above characteristics, Kerui Refractories will give you the following material selection suggestions for reference only.

| Preheater system | Ordinary alkali-resistant bricks, alkali-resistant castables, anti-skinning refractory castables |

| Precalciner | Anti-stripping high alumina brick, anti-skinning refractory castable, high alumina low cement refractory castable |

| Thermal insulation materials | Calcium silicate board, refractory fiber, insulation brick, lightweight castable |

The refractory materials used in the rotary kiln system are as follows:

| Firing zone | Upper and lower transition zone | Decomposition zone | Front and back kiln mouth | seat belt | Coal injection pipe |

| Magnesia-chrome brick magnesium iron spinel brick magnesium zirconia brick , magnesium and calcium brick |

Spinel brick, magnesia zirconia brick, silicon molybdenum brick, anti-stripping high alumina brick |

Spinel brick Antistripping high alumina bricks silicon Mo brick high alumina bricks |

Corundum, corundum – mullite, high alumina refractory castable phosphate bricks, steel fiber reinforced phosphate bricks |

Anti-stripping High Alumina Brick Silica Moro Brick Phosphate Brick |

Corundum – mullite castable steel fiber reinforced castable low cement high aluminum castable |