- 07

- Nov

SK32 clay brick, SK34 clay brick, SK36 high alumina brick, SK37 high alumina brick, SK38 refractory brick price performance index

SK32 clay brick, SK34 clay brick, SK36 high alumina brick, SK37 high alumina brick, SK38 refractory brick price performance index

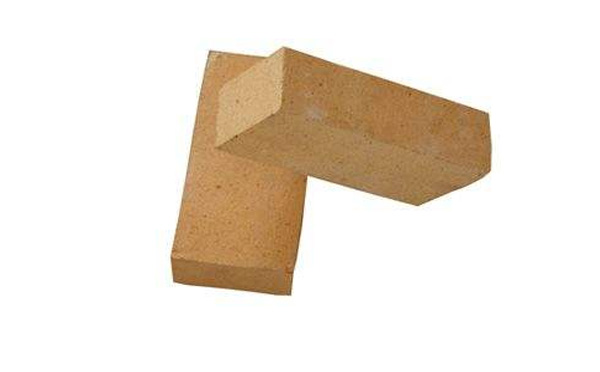

High-temperature-resistant bricks are called refractory bricks. It is a finished product obtained by mixing refractory clay with clinker (calcined and pulverized clay), then stirring, pressing into a shape, drying and calcining. There are also siliceous and high alumina bricks. According to the grades, it can be divided into SK32, SK34, SK36, SK38, and SK40 refractory bricks. Refractory bricks are mainly used in furnace linings, flues, chimneys, etc. According to their shapes and specifications, they can be divided into two categories: standard and special. The specifications of standard refractory bricks are 230 mm × 114 mm × 65 mm, and special-shaped refractory bricks are processed on-site according to demand or supplied by the manufacturer.

Refractory bricks can be divided into two types according to their fire resistance degree (the degree of fire resistance is 1580~1770℃ and the high grade refractory brick (the degree of fire resistance is 1770~2000℃). According to their chemical properties, they can be divided into acidic, alkaline and neutral. 3 types.

Our company is a professional refractory brick manufacturer with nearly 30 years of establishment, mainly including SK series refractory bricks, special-grade refractory bricks, first-class refractory bricks, second-class refractory bricks, special-shaped refractory bricks; we continue to promote high-tech and new technology; The product quality meets the needs of different customers; the National Ceramic and Refractory Product Quality Supervision and Inspection Center regularly supervises and inspects to ensure the stability of product quality.

Refractory bricks have abrasion resistance, corrosion resistance, spalling resistance, low creep, good thermal shock stability, and their service life is 1.5 times that of ordinary products; mainly used in blast furnaces, hot blast stoves, carbon roasters, carbon calciners, coke ovens , Steel drums, casting systems, boilers, cement kilns, glass kilns and various kiln linings and thermal equipment, etc., suitable for metallurgy, machinery, building materials, casting, ceramics, electric power, petroleum, chemical industries and other industries.

The physical and chemical indexes of SK32, SK34, SK36, SK38, SK40 refractory bricks.

| project | Clay brick | High alumina brick | ||||||

| SK-30 | SK-32 | SK-34 | SK-35 | SK-36 | SK-37 | SK-38 | SK-40 | |

| AL2O3% (≥) | 30 | 35 | 38 | 45 | 55 | 65 | 70 | 82 |

| Fe2O3% (≤) | 2.5 | 2.5 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Refractoriness (SK) | 30 | 32 | 34 | 35 | 36 | 37 | 38 | 40 |

| Load softening temperature, 0.2MPa, °C (≥) | 1250 | 1350 | 1370 | 1420 | 1450 | 1480 | 1530 | 1600 |

| Porosity (%) | 22-26 | 20-24 | 20-22 | 18-20 | 20-23 | 20-23 | 20-22 | 18-20 |

| Density (g/cm³) | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 | 2.25-2.4 | 2.3-2.5 | 2.4-2.6 | 2.5-2.7 |

| Compressive strength at room temperature, MPa (≥) | 20 | 25 | 30 | 40 | 45 | 50 | 60 | 70 |