- 28

- Nov

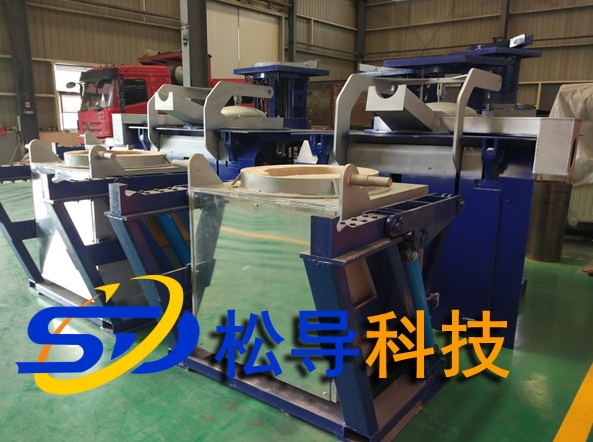

Special furnace for precision casting

Special furnace for precision casting

●Product introduction

▲ SD type precision casting special furnace is a new type of special precision casting furnace developed by our company according to the process requirements of precision casting, combined with years of R&D and production experience of intermediate frequency furnace.

▲The equipment adopts SD series resonance intermediate frequency power supply and special furnace body. Compared with traditional equipment, it has been greatly improved in terms of energy consumption and stability. The average energy consumption is controlled within 550Kw.H/T. At present, it has saved 50 million kWh of electricity for hundreds of precision casting enterprises.

▲High-power power supply and reasonable coil matching can shorten the melting speed to 20 minutes/furnace, which greatly improves production efficiency while reducing losses.

▲I5 intelligent detection and remote monitoring system can be installed, which has great advantages in technology, production process and actual parameters.

●Main advantages

▲Low energy consumption-the measured energy consumption is within 550Kw.H/T.

▲Fast melting speed-the measured melting speed is 20Min/furnace.

▲High degree of intelligence-can be equipped with i5 remote intelligent cloud system.

▲The product design is highly pertinent–breaking the traditional furnace structure, making the intermediate frequency furnace more suitable for the precision casting process.

●HQ hydraulic steel shell furnace body

▲The hydraulic steel shell furnace body structure is adopted, which provides a foundation for the expansion of the furnace body. Various extended functions can be customized according to user needs to improve stability and reduce labor intensity of workers.

●Main advantages

▲The shell is made of stainless steel and aluminum plate, with high strength;

▲The hydraulic system is used for tilting the furnace, and the stability is stronger;

▲The tilting angle can be controlled freely, making it easier to operate;

▲Function customization can be carried out according to user needs;

●Extended function

▲It can realize fixed-point and quantitative casting (customized kit required)

▲Automatic casting can be realized (customized kit required)

▲Automatic dust removal function can be realized (customized kit required)

●HQ reducer aluminum shell furnace body

▲It adopts a reducer square shell furnace body structure, which belongs to traditional equipment with simple structure and low production cost. However, it has poor scalability and is suitable for conventional precision casting processes that do not require high scalability.

●Main advantages

▲Using square shell furnace body structure, simple structure

▲Made by traditional craftsmanship, low cost

▲Small capacity furnace body can adopt manual tilting furnace