- 01

- Dec

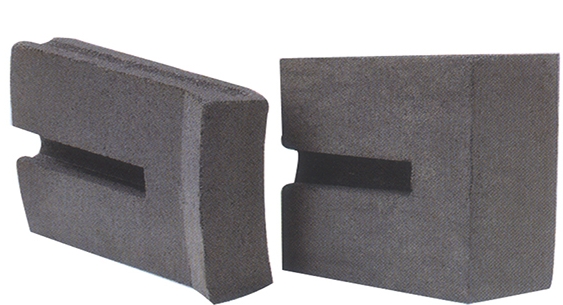

How to distinguish the quality of high alumina bricks?

How to distinguish the quality of high alumina bricks?

high alumina brick is a refractory material with alumina as the main component. The production process of high alumina bricks is similar to that of multi-clinker clay bricks. The difference is that the proportion of clinker in the mixture is very high, which can be as high as 90-95%. Before crushing, the clinker needs to be sorted and screened to remove iron, and the firing temperature is relatively high. When high alumina bricks such as I and II are fired in a tunnel kiln, the temperature is generally between 1500 and 1600°C.

1. Appearance color and appearance lubricity

Seeing a high alumina brick, we first look at its appearance, color and external lubricity. Some high alumina bricks are not of very good quality, resulting in poor appearance of lubricity, and the strength of high alumina bricks is not good.

The uniformity of the appearance and color of high alumina bricks reflects whether the materials are uniformly mixed during the production process of high alumina bricks. The uneven distribution of materials will lead to uneven distribution of the strength of the high-alumina bricks, thereby reducing the overall strength and service life of the high-alumina bricks.

2, external impurities

In addition, we often see some black spots on the surface of high alumina bricks. These are all impurities in the raw materials. In theory, the less impurities the better. Since these impurities are mostly iron oxide, they are simply reduced to molten iron in the high temperature environment in the kiln, which will damage the structure of high alumina bricks and affect the service life of high alumina bricks.