- 17

- Dec

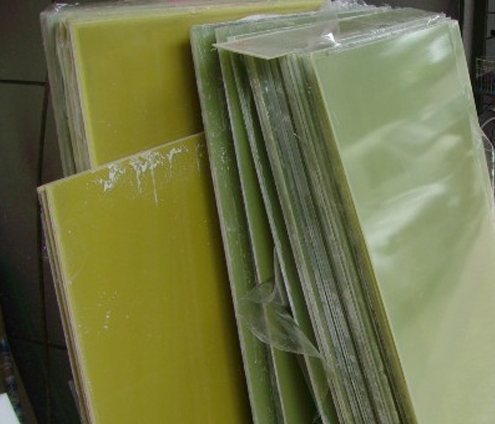

3240 epoxy resin board performance advantages

3240 epoxy resin board performance advantages

1. Various forms: various resins, curing agents, and modifier systems can almost adapt to the requirements of various applications on the form, and the range can be from extremely low viscosity to high melting point solids.

2. Convenient curing: Choose a variety of different curing agents, and the epoxy resin system can be cured at a temperature range of 0~180℃.

3. Strong adhesion: The inherent polar hydroxyl and ether bonds in the molecular chain of epoxy resin make it have high adhesion to various substances, low shrinkage during curing, and low internal stress. , Which also helps to improve adhesion strength.

4. Low shrinkage: The reaction of epoxy resin and curing agent is carried out by direct addition reaction or ring-opening polymerization reaction of epoxy group in resin molecule, and no water or other volatile by-products are released. Compared with unsaturated polyester resins and phenolic resins, they show very low shrinkage (less than 2%) during curing.

5. Mechanical properties: The cured epoxy resin system has excellent mechanical properties.

6. Appearance: Appearance includes surface finish and color. my country’s traditional standards and current standards have no color regulations, that is, all are natural colors. Some national standards allow several prescribed colors. These colors are obtained by adding colorants. Because any colorant has a negative impact on the performance of the board, considering the specific application of the insulation board, natural color should be better; in the related production process, stainless steel equipment is used to make the light Color products, such as the use of ordinary carbon steel equipment, the color of the product becomes darker; in addition, the color will become darker with the extension of storage time, so the color of the plate seen on different occasions is diverse.