- 04

- Jan

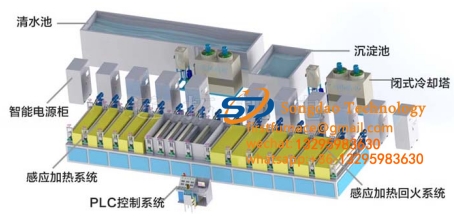

Steel plate quenching and tempering production line

Steel plate quenching and tempering production line

The steel plate quenching and tempering production line is widely used in the steel plate quenching and tempering heat treatment process. Our company specializes in the production of steel plate quenching and tempering production line. The intermediate frequency induction heating equipment has the performance of working stability, reliability and safety. These characteristics are the guarantee for the normal and stable operation of the induction heat treatment production line. The heating, quenching, tempering, workpiece running speed, heating temperature and heating efficiency of the steel plate quenching and tempering production line are all centrally controlled by PLC. A closed-loop control system can be established to realize the recording, filing, query, and printing of all production data. The data can be stored for more than 10 years.

Advantages of steel plate quenching and tempering production line:

• The steel plate quenching and tempering production line can improve the working environment and make employees more comfortable and happy to work.

• Uniform heating temperature, increase the life of the workpiece.

• Work continuously for 24 hours without interruption.

• No flammable gas, no pollution.

• The heating is rapid, and the production of oxide scale is small.

• Easy to operate and maintain.