- 11

- Jan

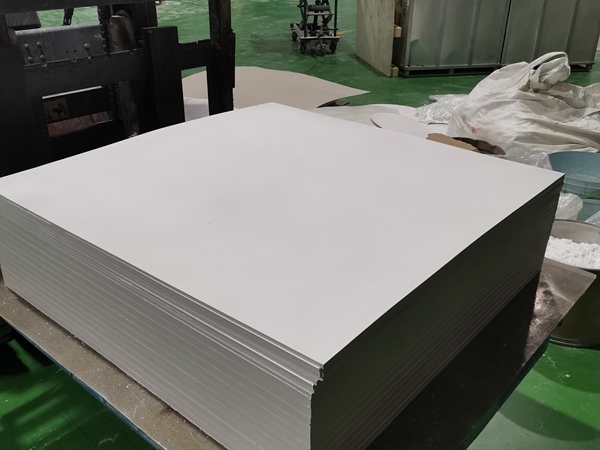

Teflon molded board

Teflon molded board

PTFE molded board, PTFE molded board 10mm, PTFE board 20mm, PTFE backing board manufacturers can customize PTFE board.

Engineering plastic with excellent comprehensive performance, its excellent performance is unmatched by other plastics. The advantages are as follows:

1. A wide range of high and low temperature applications. It can be used for a long time in the range of -180℃~250℃;

Second, excellent chemical stability. Corrosive media such as strong acid, strong alkali, strong oxidant, etc. cannot have any effect on it;

Three, a high degree of electrical insulation. Unaffected by environmental conditions and frequency, it is a Class C insulating material;

Four. It has good lubricity. After adding different types of filler materials, it can enhance the hardness and wear resistance, and it is an ideal material for oil-free lubrication;

5. Good weather resistance. Exposure to the atmosphere for many years, the surface and its various properties remain unchanged.

1. Features: PTFE is larger

The amplitude is 2.5 meters. It is made of suspended polytetrafluoroethylene resin by molding. According to the production process, it is divided into two types: molded plate and turned plate.

Among the known plastics, PTFE has excellent chemical resistance and dielectric properties, is not aging, non-sticky, and can be used at -180℃-260℃ under no load. It is in known solid materials. It has a low coefficient of friction.

2. Performance: project unit index SFB-1SFB-2, proportion 2.10-2.30, tensile strength Mpa≥14.0,

Elongation at break %≥14.0

Item Item Density Density Voltage Withstand Voltage Tensilestrength Tensile Strength Tearelongaton Breaking Elongation Unitg/cmKV/mmMpa% Target2.10-2.3010>15>140

3. Purpose: processing and manufacturing gaskets, seals, lining partitions, scrapers, guide rails, and electrical insulators used under various frequencies, bridge support sliders