- 09

- Mar

Introduction to the varieties and materials of lightweight thermal insulation bricks

Introduction to the varieties and materials of lightweight thermal insulation bricks

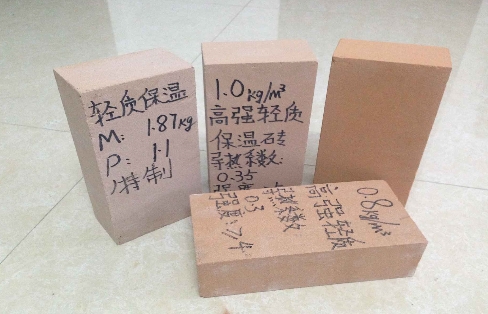

There are many types of lightweight bricks and materials. Light-weight sound-insulating bricks in construction are produced and processed by foam technology. In the refractory industry, lightweight bricks are also called lightweight heat-insulating refractory bricks, which can not only effectively save energy and heat And it can be used at a certain temperature. Lightweight high-alumina bricks are also known as high-alumina thermal insulation bricks. The alumina content is more than 48%, and it is a lightweight refractory mainly composed of mullite and glass phase or corundum. The bulk density is 0.4~1.35g/cm3. The porosity is 66%~73%, and the compressive strength is 1~8MPa. Thermal shock resistance is better.

Lightweight high-alumina bricks usually use high-alumina bauxite clinker and a small amount of clay, after being finely ground, they are poured and shaped in the form of mud by gas generation method or foam method, and fired at 1300-1500°C. Sometimes industrial alumina can be used to replace part of bauxite clinker. It is used for the lining and heat insulation layer of masonry kilns, as well as the parts that are not corroded and scoured by strong high-temperature molten materials. When in direct contact with the flame, the surface contact temperature shall not be higher than 1350°C. Lightweight thermal insulation refractory bricks are suitable for the temperature range of 900℃~1650℃. It has the characteristics of high temperature resistance, high strength, low thermal conductivity, and remarkable energy-saving effect.