- 07

- Apr

Application principle of high frequency quenching equipment

Application principle of high frequency quenching equipment

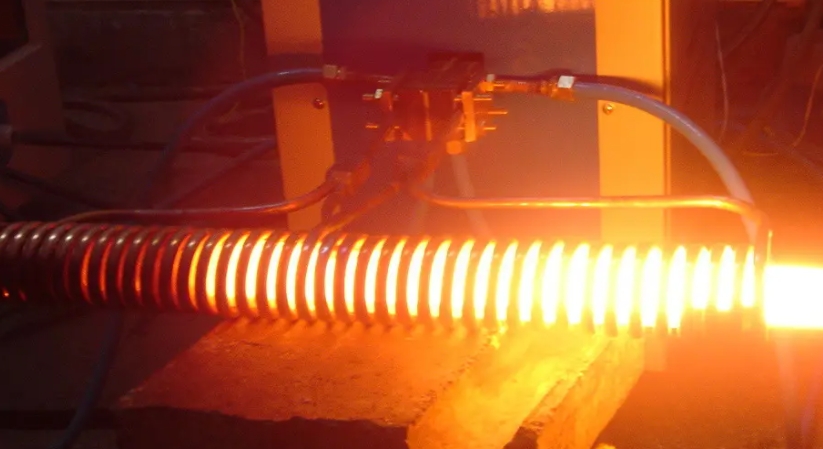

Principle: The workpiece is placed in an inductor wound with a hollow copper tube, and an induced current of the same frequency is formed on the surface of the workpiece after passing through the alternating current of the intermediate frequency or [1] inversion, and the surface or part of the part is rapidly heated (several times). The temperature can be raised to 800~1000℃ in seconds, and the heart is still close to room temperature. After a few seconds, spray (immersion) water cooling (or spray immersion oil cooling) to complete the immersion work, so that the surface or part of the workpiece reaches the corresponding hardness Require.