- 21

- Apr

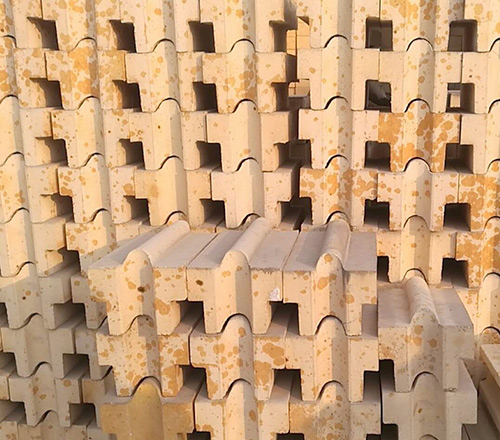

Silica brick performance introduction

Silica brick performance introduction

Silica brick is a kind of refractory commonly used in high temperature furnace equipment such as glass kiln, coke oven and hot blast stove.

Silica brick is the main type of siliceous refractory material, in which the mass fraction of SiO2 is not less than 93%. Silica brick is a typical acid refractory brick, which has excellent resistance to acid slag, and also has excellent resistance to oxides such as Al2O3, FeO, Fe2O3, but has poor resistance to basic slag, and is easily affected by CaO, K2O, It is damaged by oxides such as Na2O. The load softening temperature of silica brick is as high as 1640-1680℃, and the volume is relatively stable in long-term use at high temperature. However, silica bricks have poor thermal shock resistance and insufficient refractoriness. The properties of silica bricks, including chemical mineral composition, true density, bulk density, refractoriness, softening temperature under load, high temperature volume stability, thermal shock resistance and slag resistance, etc. and many other factors are closely related.