- 12

- May

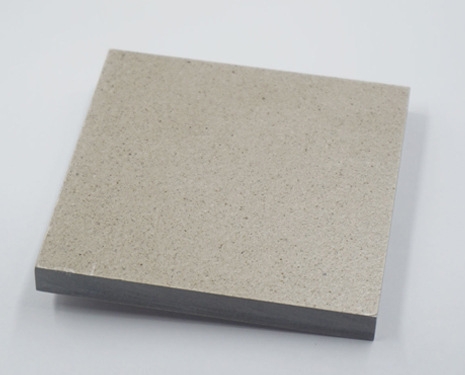

How about epoxy resin board products

How about epoxy resin board products

Resin, hardener, modifier systems are available to suit virtually every application form requirement, ranging from very low viscosities to high melting point solids. Various curing agents are used for curing, and the epoxy resin system can be cured almost in the temperature range of 0 to 180 °C.

1. Strong adhesion

The existence of polar hydroxyl and ether bonds inherent in the molecular chain of epoxy resin makes it have high adhesion to various substances. Epoxy resins have low shrinkage during curing and low internal stress, which also contributes to improved adhesion strength.

2. Strong shortening

The reaction between the epoxy resin and the curing agent used is carried out through a direct addition reaction or a ring-opening polymerization reaction of the epoxy group in the resin molecule, and no water or other volatile by-products are released. They show very low shrinkage (less than 2%) during curing compared to unsaturated polyester resins and phenolic resins.

3. Mechanical function

The cured epoxy resin system has excellent mechanical properties.

4. Electric function

The cured epoxy resin system is an excellent insulating material with high dielectric properties, surface leakage resistance and arc resistance.

5. Chemical stability

Generally, the cured epoxy resin system has excellent alkali resistance, acid resistance and solvent resistance. Like other functions of cured epoxy systems, chemical stability depends on the selected resin and curing agent. Appropriate selection of epoxy resin and curing agent can make it have special chemical stability function.

6. Scale stability

The combination of many of the above features gives epoxy resin systems excellent dimensional stability and durability.

7. Mold resistant

Cured epoxy systems are resistant to most molds and can be used in harsh tropical conditions.