- 10

- Jun

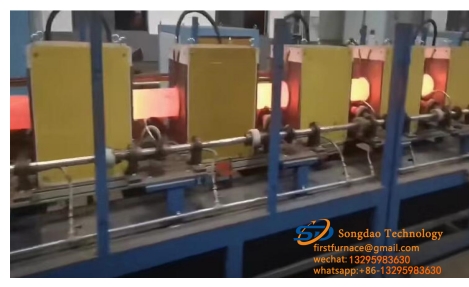

Induction heating equipment for round steel

Induction heating equipment for round steel

The equipment composition of induction heating round steel includes intermediate frequency power supply, electric heating capacitor, induction furnace body, water cooling cable connected by pneumatic or electric pushing material, and HSBL cooling circulating water system.

The equipment for induction heating round steel also includes step feeding or washboard feeding, conveying device, automatic feeding and sorting device, flat vibration feeding or chain feeding device, pressing roller feeding device, automatic temperature control system and three sorting device.

The intermediate frequency power supply of the induction heating equipment is mainly composed of the following unit circuits: rectification filter unit, inverter unit, adjustment unit, drive unit, resonance unit, protection unit. The induction coil generates an alternating magnetic field, which can penetrate the workpiece placed in the induction coil to induce a current in the workpiece itself and rapidly heat the workpiece.

The induction heating equipment of round steel is composed of induction coil, bakelite column, copper screw, busbar, furnace mouth plate, inductor bottom bracket, bakelite shell, temperature measuring device, insulation layer, cooling water circuit, etc. , According to the specifications of the heating workpiece and the process parameters of the workpiece, it is specially designed. The entire induction heating coil is wound from a high-quality rectangular copper tube. The cooling water is passed through the tube, and the surface of the induction coil uses special insulation materials , to strengthen its insulation strength and reduce heat loss. In order to protect the coil insulation layer, the lining is knotted by the pouring method, and a cooling water distributor is configured to give the inductor a good and timely cooling.