- 05

- Jul

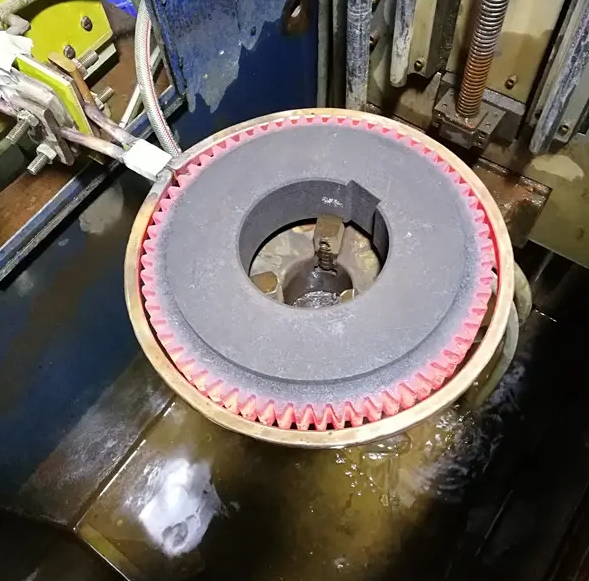

Surface induction hardening equipment – superheat heat treatment phenomenon

Surface induction hardening equipment – superheat heat treatment phenomenon

Ordinary overheating: the heating temperature of the surface induction hardening device is too high or the holding time at high temperature is too long, which causes the austenite grains to become coarser, which is called overheating. In the quenching process, the coarse austenite grains easily lead to a decrease in the strength and toughness of the steel, which increases the brittle transition temperature and increases the possibility of deformation and cracking.

The reasons for overheating are: furnace temperature instrument failure or mixing (usually ignorance of the process).

Under normal conditions, the superheated structure is annealed, normalized or repeatedly tempered at high temperature, and then austenitized to refine the grains.