- 20

- Jul

Cooling water is the “life” of induction furnace

Cooling water is the “life” of induction furnace

- Cooling water is the “life” of the induction furnace . When hard water is heated, it is easy to produce dirt and block the pipes. Therefore, it is recommended that the intermediate frequency power supply cabinet and capacitors be cooled by soft water coolers.

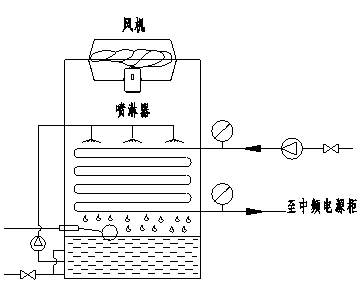

- FL-350B closed cooler: This cooling unit can be used to cool two 500kw intermediate frequency power supplies at the same time. It uses pure water (softened water) as the cooling medium, serpentine copper pipes as the radiator, and fully enclosed circulating water. The heat is taken away by the action of a fan. If necessary, the cooling effect can be enhanced by spraying water with a sprayer. The water temperature sensor is installed in the return water main pipe, and the cooling effect can be controlled in the whole process during operation. Its cooling principle is as shown in the figure:

- Technical parameters of FL-350B soft water cooler:

| model | cool down

Capacity kcal/h |

Work

Water pressure M pa |

Work

flow m3/h |

In and out

Pipe diameter mm |

rated power

Water pump/fan kw |

Water tank

capacity kg |

shape

size m |

weight

kg |

| FL-350 | 105000 | 0.25 | 12-25 | DN50 | 1.1 / 3.0 | 400 | 3.1×1.1×2.0 | 1080 |

- Cooler matching range:

set of shell (galvanized panel)

set of cooler (red copper tube)

fan (aluminum alloy blades)

spray pump

set of water collection tank (stainless steel material)

set of dehydrator (made of PVC material)

main water pump

stainless steel circulating water tank (0.5M 3 )

set of electric control box (with temperature control system)

5. External circulating water cooling system: The external circulating water system includes equipment and facilities such as circulating pools, water pumps, pipeline gate valves, etc., which are specifically used to cool induction coils. The equipment and facilities are built by the user. Technical indicators of external circulating water:

Cooling water inlet temperature : 5~35℃

Outlet temperature of cooling water: ≤55℃

Cooling water pressure: 0.30Mpa~0.40MPa

Water supply (water pump flow): 18m 3 /h (total for two furnaces)

Slope of return pipe: i=0.01

Cooling water quality requirements:

PH value: 7~8.5

Total hardness: ≤10 degrees (10 mg CaO in 1 liter of water)

The effective volume of the cooling water pool is not less than 50m 3 . (For two stoves)